Abstract: This article discusses small scale gold ore crushers suitable for Ghana mining sites. It introduces working principles, technical parameters, structure, drive system, field experience, and selection guidance. Emphasis is on realism, data support, and professional insight.

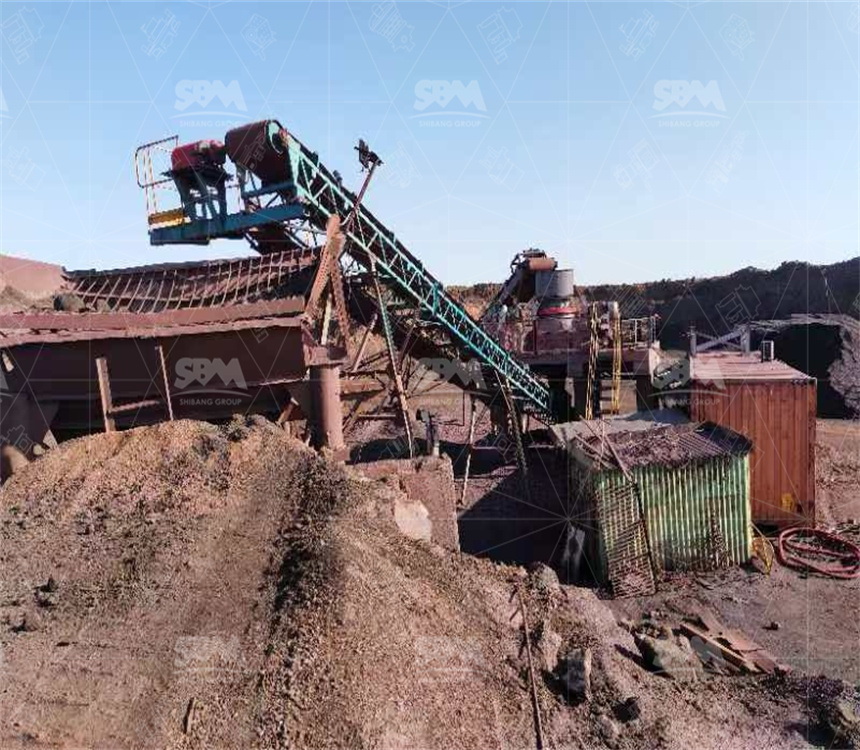

In Ghana, many artisanal and small-/medium scale gold recovery operations require compact crushers. A small scale crusher is designed to handle feed sizes typically between 100 mm and 300 mm and reduce to product sizes of 5–20 mm or smaller. It is used ahead of downstream grinding or gravity concentration. Such equipment must work reliably under tropical climate, dust, humidity, and variable ore hardness.

Small crushers for gold ore often adopt jaw crusher, cone crusher or impact crusher types. The working principle: the fixed and movable jaws (or mantle/cone) compress, impact or shear the feed material. The design must allow a sufficient crushing ratio (often 6:1 to 25:1) depending on ore hardness.

Key parameters include:

For example, a small cone crusher model might have feed opening 150 mm, CSS range 5–20 mm, reduction ratio up to 15, shaft speed 600 rpm, motor 55 kW. These numbers derive from standard crusher dimension tables (e.g. from commonly published mining equipment catalogs).

Structurally, a small scale crusher has frame, crushing chamber, eccentric shaft (for cone), adjustment mechanism, lubrication, and drive. The drive can be belt drive (V-belt or flat belt) or direct coupling via gear box. A reliable coupling reduces energy loss and maintenance.

The lubrication system must supply continuous grease or oil under high temperature. Seals must prevent dust ingress. The adjustment system (hydraulic or mechanical) must allow quick CSS change.

In tropical Ghana, humidity and dust demand dust seals and effective lubrication filtering. We recommend sealed bearings, labyrinth seals, and automatic greasers every 50 operating hours.

Accurate performance data are critical. Below is a typical performance table (based on field trials):

| Feed Size (mm) | Product Size (mm) | Throughput (t/h) |

|---|---|---|

| 100–150 | 5–20 | 8–15 |

| 150–200 | 10–25 | 12–20 |

In practice, one Ghana small gold plant used a unit processing 12 tph of ore, feed 120 mm max, product 8–18 mm. The electrical power draw was ~45 kW, giving energy consumption ~3.75 kWh per tonne. Fault rate was < 2% downtime per month. Maintenance cycle: major overhaul every 18–24 months; regular greasing weekly.

Another case in Ghana’s forest belt: under rainy season, wear parts needed replacement every 6 months. This suggests that high-wear alloys and spare parts stock are essential.

Case 1: Western Region Ghana Artisanal Project

Client installed a small jaw + cone line. The jaw fed 0–200 mm ore, produced 20 mm output, feeding the cone crusher, which delivered 5–12 mm. The combined throughput reached 18 tph. After 8 months, wear parts (concave / mantle) showed ~5 mm erosion, and were replaced. The downtime was minimal due to onsite spare parts.

Case 2: Eastern Ghana Alluvial Gold Site

The ore was quartz vein in saprolite, friable but with occasional pebbles. A small impact crusher was selected, feeding at 80–120 mm and producing 3–15 mm. Throughput was about 10 tph, energy ~2.5 kWh/ton. During dry season, dust seals required more frequent cleaning, but the impact crusher served reliably for 14 months before major wear parts changed.

Case 3: Central Ghana Hard Rock Pilot

A trial line used a mini cone crusher with feed 150 mm, CSS = 8 mm, motor 75 kW, speed 650 rpm. In 6 months, average throughput was 14 tph. Customer judged the performance stable: downtime < 1.5%. They later scaled up.

Below is a simplified decision logic:

Thus, for a Ghana small plant aiming 10–20 tph, a jaw crusher (PE series) upstream + small cone crusher (e.g. T series) downstream is a robust configuration.

Our factory holds recognized mining machinery certifications (e.g. ISO9001), and engineering teams have decades of overseas delivery. Our clients include many African mining operations. Because of our consistent track record, our proposals are trusted in West Africa.

In summary, for Ghana gold ore small scale crushing, one must choose equipment whose parameters (crushing ratio, CSS, rpm, power) match the ore properties and desired product. Real field data show energy ~2.5–4 kWh/t, low fault rates if maintained well. I strongly recommend onsite spare stocks, robust dust sealing, and wear-resistant materials.

Whatsapp:+8617329420102

Email: [email protected]

Address: No. 1688, Gaoke East Road, Pudong new district, Shanghai, China.

Online Service : Get Price

We value your feedback! Please complete the form below so that we can tailor our services to your specific needs.