Gold mining is a tough business. You need the right plan. Small scale miners often struggle with hard rock. The ore is difficult to break. It wears down machines quickly. We understand these challenges well. SBM has helped many miners. We know how to get gold out efficiently. This guide shows a clear flowchart. It is simple to follow. It uses proven technology. We focus on profit and stability. Let’s look at the process.

Hard rock gold is locked inside stone. You cannot wash it out easily. It is different from alluvial gold. You must break the stone first. This requires strong force. The rock type matters a lot. Quartz is very common. It is hard and abrasive. It eats steel parts. You need a specific flowchart.

We test the ore first. This is called mineral processing experiments. It tells us the “work index”. This measures how hard the rock is. High work index means more power needed. We also check gold particle size. Fine gold needs fine grinding. Coarse gold needs gravity separation. Knowing this saves money later.

According to the International Journal of Mineral Processing, testing saves 20% operating costs. Don’t guess. Test your ore. It is the first step to success. SBM labs can do this for you.

The first stage is crushing. We use a Jaw Crusher here. It is strong and reliable. The model is usually the PE Series. It works like a giant mouth. It chews the big rocks. The principle is “squeeze crushing”. A moving jaw presses rock against a fixed jaw. The rock breaks into smaller pieces.

Key parameters are vital. One is the CSS (Closed Side Setting). This is the smallest gap at the bottom. It controls the output size. For small scale, set it to 40-60mm. Another is the OSS (Open Side Setting). This is the widest gap. It affects how fast rock flows. A proper ratio is key. Minerals Engineering journal states correct CSS reduces energy by 15%.

Why use a Jaw Crusher? It handles high impact. The eccentric shaft drives the movement. The toggle plate protects the machine. If a metal piece enters, the plate breaks. The machine stops safely. This prevents major damage. It is a smart design. We use high manganese steel for jaw plates. It lasts longer against quartz.

| Model | Feed Size (mm) | Output Size (mm) | Power (kW) |

|---|---|---|---|

| PE-400×600 | 340 | 40-100 | 30 |

| PE-250×400 | 210 | 20-60 | 15 |

| PE-150×250 | 125 | 10-40 | 5.5 |

Big rocks are now small stones. But they are not small enough. The ball mill needs fine food. Big stones hurt the mill efficiency. We need a second crusher. The Fine Jaw Crusher is good here. Or a small Cone Crusher. For small scale, Fine Jaw is cheaper. It is simple to fix.

This stage reduces stone to 15-20mm. This is a critical size. We call it “more crushing, less grinding”. Crushing uses less power than grinding. So, we crush more. This is a golden rule. It lowers the electricity bill. Many miners skip this. They lose money on energy.

The PEX series is popular. It runs faster than the big jaw. It creates more fines. The reduction ratio is higher. We check the motor power match. It must handle the load. SBM engineers calculate this precisely. We ensure the motor does not burn out.

Now the stone enters the Ball Mill. This is the heart of the plant. The mill is a rotating drum. It is filled with steel balls. The drum spins. The balls drop on the ore. This impacts breaks the rock to dust. The gold is finally free. This is called liberation.

We look at “Critical Speed”. This is the speed where balls stick to the wall. They don’t drop. The mill must run slower than this. Usually 75% of critical speed. Powder Technology journal confirms this is optimal. It gives the best impact force. We also watch the ball load. Too many balls waste power. Too few balls don’t grind well.

Why use a grid ball mill? It prevents over-grinding. Gold is soft. If you grind too much, it smears. It becomes hard to catch. Our grid design lets fine ore leave quickly. It keeps the gold shape. This improves recovery rates. The liner material is also key. We use rubber liners often. They last long and are quiet.

Free gold is heavy. Rock is light. We use gravity to separate them. This is cheap and green. No chemicals are needed yet. A Centrifugal Concentrator is the best tool. It spins very fast. It creates high G-force. Heavy gold sticks to the side. Light sand washes away.

It captures fine gold well. It works for particles down to 20 microns. After the concentrator, we use a Shaking Table. It cleans the concentrate. You can see the gold line. It is very satisfying. You get high grade gold directly. This creates cash flow quickly.

Why do we put this early? To recover coarse gold fast. If coarse gold goes to tanks, it sinks. It takes too long to dissolve. Removing it early is safer. It prevents gold theft too. The gold is in your safe box sooner. This is smart business.

Let’s look at a real story. Mr. Ahmed in Sudan had a mine. It was small, 50 tons per day. The rock was hard quartz. He used simple hammer mills before. They broke every week. He was losing money on parts. He called SBM for help.

We changed his design. We installed a PE-400×600 Jaw Crusher. Then a MQG1530 Ball Mill. We added a spiral chute for roughing. The result was amazing. His recovery rate went from 60% to 92%. The machine downtime stopped. He made his money back in 4 months.

Mr. Ahmed said: “The SBM crusher is a beast. It eats the hard rock easily. I don’t worry about repairs now. I sleep better at night.” This proves quality pays off. Cheap machines are expensive in the long run.

This is a common pain point. You crush, you grind, but gold is lost. Why? Usually, the grind size is wrong. If rock is too big, gold is locked. If rock is too small, gold floats away. You need a stable classifier. It controls the size perfectly.

Another reason is clay. Clay steals gold. It coats the particles. Chemicals cannot touch the gold. You must wash the ore. A washing drum helps. We add this before crushing. It removes the sticky clay. Your recovery will jump up immediately.

Yes, but you need a plan. Machines need rest or care. A standby generator is a must. Power cuts stop the flow. Slurry settles in pipes. It turns to concrete. Restarting is a nightmare. You need backup power.

You also need spare parts on site. Don’t buy parts when it breaks. Have them ready. Jaw plates, liners, and belts. Keep them in a shed. This reduces downtime. SBM provides a spare parts list. We tell you what to keep. It is like a first aid kit.

For small scale, maybe. Cyanide plants are complex. They need strict safety. They need engineers. If you are small, stick to gravity. It recovers 70-80% of gold. It is safe and easy. You can sell the tailings later. Or process them when you grow big.

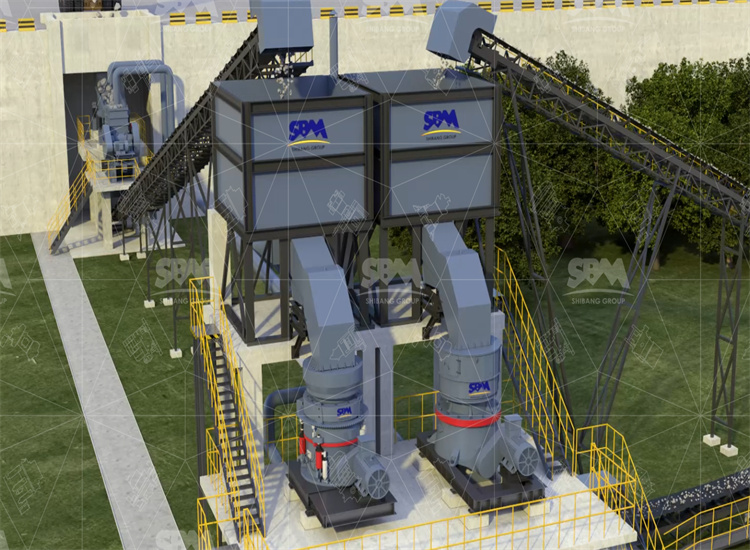

However, SBM has a solution. We have a containerized CIL plant. It is a mini chemical factory. It comes in a box. It is easy to install. It gets 95% recovery. It costs more upfront. But it wastes less gold. We calculate the ROI for you. You can decide based on numbers.

Installing is not just placing machines. It is about flow. Gravity must help you. We build on slopes if possible. Slurry flows down naturally. This saves pump power. It saves money every hour. We design the layout carefully.

Foundations must be strong. Hard rock crushing creates vibration. Weak concrete will crack. We give detailed drawings. Your local builder can follow them. Or we send a SBM engineer. He guides the team. He ensures it is level and firm.

We also train your workers. They need to know the sounds. A happy crusher sounds rhythmic. An unhappy one bangs. We teach them to listen. We teach them to grease. Daily maintenance prevents big failures. Your team becomes expert.

Check the oil daily. The toggle plate needs grease. The ball mill gears need lube. Dust is the enemy. It destroys bearings. Keep the motor clean. Cover it from rain. Simple habits save thousands of dollars.

Tighten the bolts. Vibration loosens them. Check them once a week. A loose bolt causes cracks. Replace wear parts in time. Don’t wait until they break. A worn liner destroys the shell. The shell is expensive. The liner is cheap. Be smart.

Keep a logbook. Write down repairs. Write down oil changes. This tracks machine health. It helps sell the mine later. A documented plant is worth more. SBM helps set up these logs. We want you to succeed for years.

1. How much water do I need?

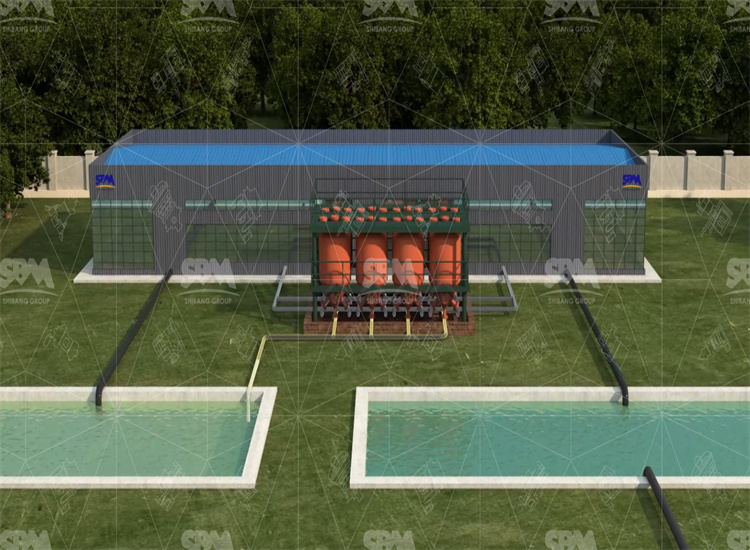

Water is vital. Generally, you need 3 to 5 tons of water for 1 ton of ore. It depends on the clay. Gravity separators use more. We can recycle water. We use a thickener tank. It reclaims 80% of water. This is good for dry areas.

2. Can I process different ores?

Be careful. Oxide ore is soft. Sulfide ore is hard. They behave differently. The crusher settings change. The chemical needs change. It is best to stick to one type. Or blend them consistently. Sudden changes upset the mill.

3. How long to build the plant?

Small plants are fast. Manufacturing takes 1 month. Shipping takes 1 month. Installation takes 1 month. In 3-4 months, you can produce gold. SBM speeds this up. We have modular designs. They plug and play. Time is money.

Whatsapp:+8617329420102

Email: [email protected]

Address: No. 1688, Gaoke East Road, Pudong new district, Shanghai, China.

Online Service : Get Price

We value your feedback! Please complete the form below so that we can tailor our services to your specific needs.