You might be throwing money away. Many mines lose gold in tailings. This article tells you how to catch it. We use SBM equipment to help. Simple tools make big money. Read this to fix your plant.

Fine gold is very small. It is hard to catch. Gravity separation often misses it. The particles are under 50 microns. They float away with water. This is a big problem. Miners lose 30% of profits here. Old machines are too slow. They cannot see the gold. We need better physics. The industry calls this “locking”. The gold sticks to waste rock. You need to grind it finer. But grinding costs money. You must balance the cost.

This is the king of fine gold. It spins very fast. It works like a washing machine dry cycle. It creates high gravity force. We call this G-force. Normal gravity is 1G. This machine makes 60G to 90G.

How it works:

The bowl spins. Water pushes from the outside. This is fluidization water. It keeps the bed loose. Heavy gold gets trapped. Light sand washes out.

Why use it:

It captures particles down to 20 microns. Minerals Engineering journal says 60G is best. It recovers 98% of free gold. It uses less water than jigs.

Key Specs:

Feed size must be -4mm. SBM models handle 10 to 100 tons per hour. The motor power matches the bowl size.

| Model | Capacity (t/h) | Power (kW) |

|---|---|---|

| ST-30 | 10-15 | 7.5 |

| ST-60 | 30-45 | 15 |

| ST-100 | 80-100 | 30 |

You probably use sluice boxes. Sluice boxes are cheap. But they are weak. They need big gold nuggets. Fine gold flows over the riffles. The water speed is too high. Turbulence lifts the gold. Sluice recovery is often only 40%. That is bad. You leave 60% in the tailings. That is lost cash. You need to upgrade. Sluice boxes are for 1900s. Centrifuges are for 2025.

After the concentrator you have concentrate. But it still has sand. You need to clean it. The SBM 6S Shaking Table is best. It separates by density.

Principle:

The table shakes back and forth. It has a slope. Water flows down. Gold moves sideways. Lighter sand washes down. You see a gold line. We call it the “yellow snake”.

Why use it:

It is very precise. You get sellable gold directly. The recovery rate is high.

Technical Data:

Stroke length is 10-30mm. Stroke rate is 60-80 times per minute. The deck is fiber glass. It lasts a long time. It resists wear.

Sometimes gravity is not enough. The gold is inside the sulfide. This is “refractory gold”. You might need flotation.

SBM Flotation Cells:

We mix rock with bubbles. We add chemicals. Xanthate is common. Gold sticks to bubbles. Bubbles float to top.

Efficiency:

Flotation catches the finest dust. Even 5 microns. But it costs more. You need chemical experts. It is good for large mines. Small miners prefer gravity. Gravity is chemical-free. It is safer.

We helped a client in Ghana. They had an old dump. It was 500,000 tons of waste. The climate is hot and wet. The material was clay and quartz.

The Problem:

They tried cyanidation. It used too much acid. The copper killed the process. They lost money.

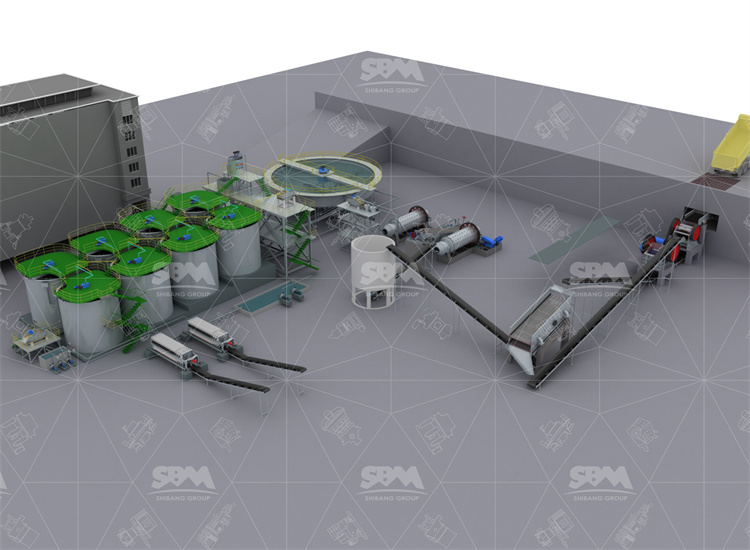

The SBM Solution:

We tested the sample. We found 2g/t gold. 60% was free gold. We installed a wash plant.

Equipment List:

1. SBM Scrubber (to wash clay).

2. SBM Centrifugal Concentrator (ST-60).

3. SBM Shaking Table.

Result:

Recovery hit 78%. They make $5000 a day. The machine paid for itself in 2 months. The client was happy. He said “SBM machine runs smooth. No headache.” maintenance is easy.

If you crush rock first. You must watch the CSS. CSS is Closed Side Setting. It sets the output size.

Why it matters:

If CSS is too big gold stays locked. If CSS is too small you waste power. You create “slimes”. Slimes are bad. Gold floats away in slimes.

The Rule:

Keep CSS near the liberation size. Use a decision tree. Measure output daily. Adjust the cone crusher tight. Check the liner wear. SBM crushers have auto-adjust. It keeps size consistent. Consistent feed equals consistent gold.

Machines break. That is a fact. But good machines break less. SBM uses strong steel. We use Mn13Cr2 liners. They last 20% longer.

Grease vs Oil:

Our concentrators use simple grease. No complex oil pumps. Less parts to fail.

Bearings:

We use SKF or Timken bearings. They handle the heat. Good bearings save the motor.

Access:

Our design is open. You can change parts fast. Down time is lost money. We minimize down time. Mechanics love our design.

This was a hard rock mine. The ore was granite. Very abrasive.

Background:

The tailings were piled high. The grade was 1.5g/t. The gold was fine. About 40 microns.

SBM Approach:

We used a Ball Mill to regrind. We targeted 80% passing 200 mesh. Then we used flotation.

Data:

Ball Mill size: 2.4m x 3.0m.

Flotation Cell: SF-4.

Outcome:

Recovery reached 85%. The client expanded the plant. They bought two more lines. They trust SBM quality.

| Item | Value | Unit |

|---|---|---|

| Feed Grade | 1.5 | g/t |

| Tailings Grade | 0.2 | g/t |

| Recovery | 85 | % |

Installation must be precise. The foundation must be flat. Concrete needs to cure.

Leveling:

The shaking table must be level. Use a spirit level. If it tilts you lose gold.

Water Supply:

Clean water is best. Dirty water blocks pipes. Use a filter. SBM provides the diagram. Follow the pipe map.

Electrical:

Check the voltage. Stable voltage protects the motor. Use a soft starter. It saves the belt.

Recovering fine gold is smart. It is free money. You need the right tools. Don’t guess. Use science.

Summary:

Use SBM Centrifuges for primary recovery. Use Shaking Tables for cleaning. Use Flotation for sulfides.

Next Step:

Test your tailings. Send us a sample. We tell you what you need. Stop losing gold today. Trust SBM technology.

Q1: How much water does the concentrator need?

It depends on the size. The ST-60 needs about 15 cubic meters per hour. But you can recycle water. Use a thickener tank. You can save 80% of water. This is good for dry areas.

Q2: Can I process clay materials?

Yes but wash it first. Clay is sticky. It blocks the riffles. Use an SBM Trommel Scrubber. It washes the clay away. Then the gold is free. Never feed raw clay to a centrifuge.

Q3: How long do the wear parts last?

It depends on the rock. For soft rock maybe 6 months. For hard granite maybe 3 months. Our polyurethane cones last long. They resist sand abrasion. Keep spares in stock. Don’t wait for breaks.

Whatsapp:+8617329420102

Email: [email protected]

Address: No. 1688, Gaoke East Road, Pudong new district, Shanghai, China.

Online Service : Get Price

We value your feedback! Please complete the form below so that we can tailor our services to your specific needs.