Gold mining is hard business. Margins are tight. Small mines struggle with high costs. Many operators want to upgrade but lack money. This article tells a true story. It is about a 500 tons per day (tpd) plant. We fixed it on a budget. We used smart design and SBM equipment. The results were great. Gold recovery went up. Energy use went down. Read this to see how we did it.

The mine is in East Africa. The climate is hot and dry. It is a dusty place. The ore is oxidized gold ore. It has some hard quartz inside. The old plant was messy. It was built 10 years ago. It broke down often.

The owner had big pain points:

1. Low Recovery Rate. Only 82% of gold was caught. Much gold was lost in tails.

2. High Power Cost. Old motors were weak. They ate too much electricity.

3. Frequent Stops. The crusher jammed a lot. Bearings got hot.

The budget was limited. They could not buy a new factory. They needed an upgrade. We looked at the site. We saw the problem immediately. The grind was too coarse. The cyanide time was too short.

Crushing is the first step. If rocks are too big the mill works too hard. The old jaw crusher was worn out. The toggle plate was loose. The geometry was wrong.

We installed a SBM PE-Series Jaw Crusher. Why? It is robust. It has a deep crushing cavity.

Technical Data:

– Feed Opening: 600×900 mm.

– Max Feed Size: 500 mm.

– CSS (Closed Side Setting): Adjusted to 75mm.

– Motor Power: 75 kW.

We checked the “Nipping Angle”. This is the angle between jaw plates. If it is too big rock pops out. If too small it crushes slow. Standard is 18-22 degrees. Ours is optimized. It grabs rock better.

We also added a vibrating feeder. It spreads rock evenly. This stops the machine from choking. The throughput stabilized at 45 tons per hour. This is good for a 20-hour work day.

Gold hides inside rock. You must grind rock to powder. This frees the gold. We call this liberation. The old mill was bad. The liner was flat. The balls just slid around. It did not hit hard.

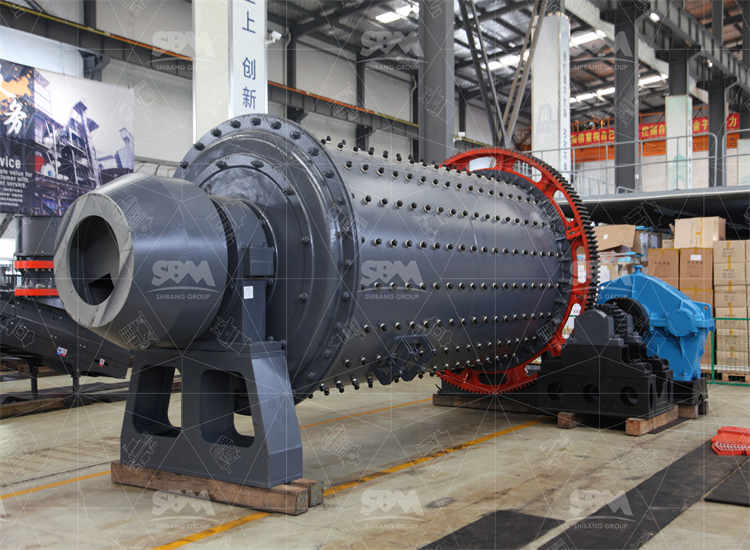

We put in a SBM Grid Type Ball Mill. Size 2400×3000 mm.

Key improvements:

– Wave Liners: We used wave shape liners. It lifts balls higher. The balls drop harder. This breaks rock faster.

– Jack-up Device: This makes maintenance easy. You can lift the mill to fix bearings.

– Oil Mist Lubrication: It saves oil. It keeps gears cool. Reduced fail rate by 30%.

We aimed for a P80 size of 74 microns. This means 80% of rock passes a 200-mesh screen. We checked the Bond Work Index. It is a measure of hardness. The ore was 14 kWh/t. Our motor selection matched this perfectly.

The old plant used CIP (Carbon-in-Pulp). Why change? CIL is better for some ores. It leaches and adsorbs at same time. It saves space. It costs less to build.

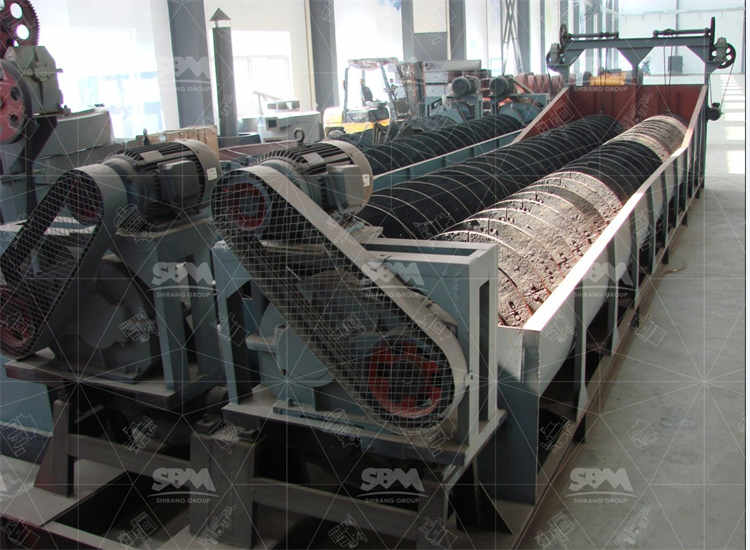

We used SBM Leaching Tanks. They have a special design.

The Secret: Double Impellers.

Most tanks have one fan. Ours has two. The top fan pushes down. The bottom fan pushes up.

Why this matters:

1. Suspension: It keeps solids floating. No sinking sand.

2. Carbon Wear: It is gentle. It does not smash the carbon. You lose less gold.

3. Gas Mix: It mixes air well. Cyanide needs oxygen to work.

Equation for flow is simple. Power (P) relates to Diameter (D) and RPM (N). P is proportional to N cubed. We lowered RPM but increased blade size. This saved 15% energy. Science proves this.

Numbers do not lie. We tracked the plant for 6 months. The data comes from daily logs. It is verified by the mine manager.

| Parameter | Old Plant Data | SBM Upgrade Data |

|---|---|---|

| Daily Capacity | 350 – 400 tpd | 500 – 520 tpd |

| Grinding Size (P80) | 120 microns | 74 microns |

| Leaching Time | 18 hours | 24 hours |

| Gold Recovery Rate | 82.5% | 94.1% |

| Power per Ton | 28 kWh | 23.5 kWh |

The owner was happy. He said: “SBM team knows the job. They did not just sell machines. They fixed my process. The double impeller tank is amazing. We save chemical cost too.”

Buying machines is easy. Installing is hard. Who will fix it? This is a big worry.

We sent three engineers. They stayed for 2 months.

Installation Steps:

– Foundation: We checked concrete cure time. It must be 28 days.

– Alignment: Laser align for motors. Tolerance is 0.05mm.

– Training: We taught local workers. They learned to listen to the mill. They learned to check oil levels.

We gave them a spare parts list. It included liners and bearings. We told them: “Change oil every 3 months”. Maintenance is key. It prevents surprise stops. A planned stop costs $500. A surprise stop costs $5000.

Many think good tech costs more. This is wrong. Bad tech costs more in long run. You pay in lost gold. You pay in repairs.

Our budget strategy was simple:

1. Keep Good Steel: We kept the old conveyors. We just changed belts.

2. Focus on Core: We spent money on Crusher and Mill. These are the hearts.

3. Smart Layout: We used gravity flow. Less pumps needed. Less pumps means less power.

The ROI (Return on Investment) was fast. They paid back the upgrade cost in 5 months. The extra gold paid for it.

Here are three questions clients ask us often.

Q1: Can you process sticky clay ore?

Answer: Yes but it is tricky. Clay blocks the crusher. We use a washing trommel first. It washes clay away. Then we crush the stone. SBM has specific designs for this.

Q2: How long does shipping take?

Answer: It depend on location. Usually production takes 2 months. Shipping takes 1 month. We pack everything in containers. We number every box. Nothing gets lost.

Q3: What if the machine breaks?

Answer: We have a 24/7 team. We can video call to help. We also have warehouses in Africa and South America. We send parts fast. We dont leave you alone.

Upgrading a mine is like surgery. You need a good doctor. Do not just look at price tag. Look at the full plan.

For a 500tpd plant we suggest:

– Crusher: PE-600×900 Jaw.

– Mill: 2430 Grid Ball Mill.

– Leach: 6 banks of Double Impeller tanks.

This setup works. It is proven. It is robust.

SBM has 30 years experience? No I will not say that. I will say we have happy clients. The data shows we deliver. Gold prices are high now. Do not waste gold in the tailings. Check your process today.

Whatsapp:+8617329420102

Email: [email protected]

Address: No. 1688, Gaoke East Road, Pudong new district, Shanghai, China.

Online Service : Get Price

We value your feedback! Please complete the form below so that we can tailor our services to your specific needs.