Old gold mines loose money every day. Machines get tired. Technology gets better. We see this a lot in the field. A client comes to us. Their recovery rates are dropping. Energy bills are going up. It is time for a change. This article looks at how to fix an old Carbon-in-Leach (CIL) plant. We will share real data. We will share real stories from SBM projects. We want to help you make more money. It is not magic. It is science and engineering.

Old equipment stops working well. It is a fact of life. We see crushers that cannot hold their settings. We see tanks that leak. This hurts your bottom line. An old plant might only recover 80% of the gold. A new plant can get 95%. Think about that difference. That is pure profit lost in the tailings. Also, old motors burn more power. They are not efficient. Safety is also a risk. Old rusty steel can break. We need to fix this.

CIL stands for Carbon-in-Leach. It is popular for gold. We grind the rock to dust. Then we mix it with water. We add cyanide to dissolve the gold. Then we add activated carbon. The carbon eats the gold. It grabs it out of the water. This happens in big tanks. If the rock is not ground enough, gold hides inside. If the carbon is old, it cannot grab the gold. Everything must work together. It is like a team sport.

The crushing stage is step one. We often use a Jaw Crusher. It uses compressive force. A moving jaw pushes rock against a fixed jaw. The motor turns an eccentric shaft. This moves the pitman. The angle is key. It creates the crushing action. We look at the Closed Side Setting (CSS). This is the smallest gap at the bottom. It decides the product size.

Why do we care? A tighter CSS means smaller rock. Smaller rock is easier for the mill. But a tight CSS wears out liners fast. You must balance this. Check the toggle plate too. It protects the machine. If a metal piece enters, the plate breaks. This saves the expensive jaw. Always keep spare toggle plates.

This is a big question. The grinding circuit eats the most power. It costs the most to run. In many old plants, the ball mill is the bottleneck. The ball mill spins a steel drum. Steel balls inside smash the rock. We aim for a specific size. Usually, 80% of the rock should be smaller than 74 microns (200 mesh). This exposes the gold. If the rock is coarse, cyanide cannot touch the gold. You lose money.

Critical speed is a vital term. It is the speed where balls stick to the wall. They do not fall. This is bad. We usually run at 70% to 76% of critical speed. According to the SME Mineral Processing Handbook, this is the sweet spot. We check this on every retrofit. Often, old mills run too slow. Or the liners are worn flat. Flat liners do not lift balls. They just slide. SBM engineers check this first.

Let’s look at a real job. This was a mine in Zimbabwe. The ore was hard quartz. The plant was 12 years old. It was processing 500 tons per day (TPD). The recovery rate was stuck at 82%. The owner was worried. He was losing gold. The climate was hot and dusty. Water was scarce. We had to be smart.

The equipment list was old. They had a single toggle jaw crusher. They had a short head cone crusher. The ball mill was a grate discharge type. The cyclone cluster was leaking. The pumps were surging. It was a mess. We did a full audit. We took samples. We tested the Bond Work Index. It was 16 kWh/t. The rock was harder than they thought. The old mill could not handle it.

We made changes. First, we changed the crusher CSS. We moved it from 25mm to 18mm. This sent smaller rock to the mill. Why did we do this? It reduced the work for the ball mill. The mill capacity went up by 15%. Next, we replaced the cyclone cluster. The old one was worn. It sent coarse rock to the tanks. The new SBM cyclones were precise. They kept the cut point sharp.

| Parameter | Before Retrofit | After SBM Retrofit |

|---|---|---|

| Crusher Product (P80) | 25 mm | 18 mm |

| Mill Product (-200 mesh) | 65% | 85% |

| Gold Recovery Rate | 82% | 93.5% |

| Cyanide Consumption | 1.2 kg/t | 0.9 kg/t |

We also added automation. Old plants use manual valves. Operators make mistakes. We added auto-feeders for cyanide. This saved chemicals. The table above shows the win. Recovery went up. Costs went down. The client was happy. He paid back the investment in six months.

Many clients ask this. “Why am I buying so much cyanide?” It is a huge cost. There are reasons. One is “cyanicides.” These are metals that eat cyanide. Copper is a bad one. Iron can be too. If your ore has copper, it steals cyanide from gold. You must know your ore. We do mineralogy tests. We check for copper. We check for organic carbon. Organic carbon is a “preg-robber.” It steals gold back.

Another reason is oxygen. Gold needs oxygen to dissolve. If your tanks have no air, reaction slows. You add more cyanide to compensate. It is a waste. We check the air blowers. We check the spargers. SBM tanks use hollow shafts. They push air deep down. This improves kinetics. It saves cyanide. Always monitor dissolved oxygen levels. Keep it above 6-7 ppm.

Here is another story. A client in Sudan had a problem. His mine had lots of clay. Sticky red mud. It clogged the crushers. It blinded the screens. The plant stopped every hour. Operators had to clean it by hand. It was a nightmare. Production was 40% of target. He called SBM.

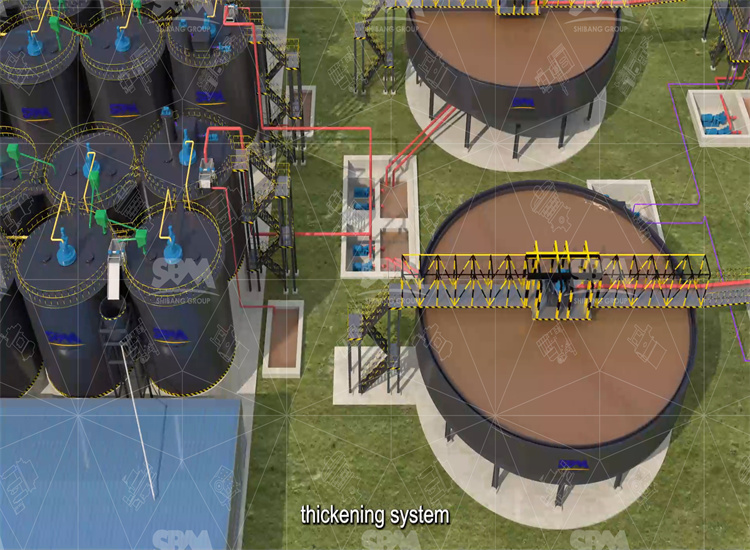

We looked at the flow. You cannot crush wet clay. We changed the design. We added a Trommel Scrubber at the start. This is a washing drum. It washes the clay away. It separates the hard rock. The rock went to the crusher. The clay went to the thickener. This solved the clogging. The plant ran smooth. The client said, “I sleep better now.” The maintenance time dropped by 80%. Simple change. Big result.

Installation matters. A good machine installed bad is a bad machine. Foundations must be level. Use a laser level. If the frame twists, bearings fail. We see this often. Concrete must cure fully. Do not rush it. Vibration will crack green concrete. Wait 28 days if you can. Or use special additives.

Maintenance is key for long life. Grease the bearings daily. Listen to the machine. A hum is good. A clank is bad. Change liners before they wear through. If the shell wears, it is expensive. Liners are cheap. Keep a logbook. Record amps. Record tons. Record downtime. Data helps you predict failures. SBM provides manuals. Read them. Train your staff. A trained operator saves you millions.

Upgrades cost money. We know that. But look at the return. In the Zimbabwe case, 10% more gold is huge. If you produce 10kg a month, that is 1kg more. At current prices, that is a lot of cash. The payback is fast. Do not just look at the price tag. Look at the value. Efficient motors save power bills. Good liners last longer. This reduces downtime. Downtime is the enemy.

We focus on “Total Cost of Ownership.” A cheap pump breaks in a week. A good SBM pump lasts months. The cheap pump stops production. That costs you gold. Buy quality. It pays off. We help you calculate this. We show you the math. It makes the decision easy.

A: It depends on the ore. Usually 24 hours is standard. Some hard ores need 36 hours. If the gold is fine, it is faster. If it is coarse, it takes longer. We do a bottle roll test to find out.

A: Change them when the teeth are gone. Or when the gap is too big. If you cannot set the CSS tight enough, change them. Do not wait for holes. Worn liners stress the frame.

A: Carbon gets dirty. Calcium and organics clog the pores. You must wash it with acid. You must regenerate it in a kiln. Heat cleans the pores. Good carbon management is vital for CIL.

Revamping a plant is smart. You do not always need a new factory. Smart upgrades work wonders. Focus on the bottlenecks. Fix the crusher settings. Optimize the grind. Manage the cyanide. Watch the carbon. These are the basics. But they are powerful. SBM has 30 years of doing this. We know the tricks. We know the pitfalls.

Every ore is different. One size does not fit all. You need a custom plan. You need data. Do the tests. Trust the science. If you have an old plant, look at it closely. Is it wasting money? Probably. Let’s fix it. Small changes make big profits. That is the goal of mining. Safe, efficient, profitable production.

Whatsapp:+8617329420102

Email: [email protected]

Address: No. 1688, Gaoke East Road, Pudong new district, Shanghai, China.

Online Service : Get Price

We value your feedback! Please complete the form below so that we can tailor our services to your specific needs.