Gold cyanidation is the main method for extracting gold. It is used globally. This process uses a cyanide solution. It dissolves gold from ore. This guide explains the steps clearly. We focus on equipment and real data. We use SBM experience here. It is for miners and investors. The content is simple. We explain technical terms. Read this to improve your plant.

Gold cyanidation is a hydrometallurgical technique. It extracts gold from low-grade ore. The process converts gold into a water-soluble complex. This happens in tanks. The tanks contain a cyanide solution. This method is efficient. It recovers widely disseminated gold.

The chemical reaction is specific. It is called the Elsner Equation. Oxygen is vital here. Without oxygen , the gold will not dissolve. The pH level must be high. Usually above 10.5. This prevents toxic gas formation. Safety is key in this step. Why do we maintain high pH. It keeps the cyanide stable. It protects the workers.

The first step is size reduction. Run-of-mine ore is too big. We must crush it. We use jaw crushers often. The PE series is popular. It uses a compressive force. The rock enters the crushing chamber. The moving jaw presses it against the fixed jaw. The rock breaks.

Key parameter is the Reduction Ratio. It measures size change. A ratio of 4:1 is common. Why is this important. It determines the next stage efficiency. Another term is CSS. This means Closed Side Setting. It controls the output size. If CSS is small , product is fine. If CSS is large , product is coarse.

We must check the toggle plate. It protects the machine. If uncrushable material enters , it breaks. This stops the machine damage. Regular inspection is needed. SBM suggests daily checks.

| Model | Feed Opening (mm) | Max Feed Size (mm) | Capacity (t/h) | Power (kW) |

|---|---|---|---|---|

| PE-400×600 | 400×600 | 340 | 16-60 | 30 |

| PE-600×900 | 600×900 | 500 | 50-180 | 55 |

| PE-900×1200 | 900×1200 | 750 | 220-450 | 110 |

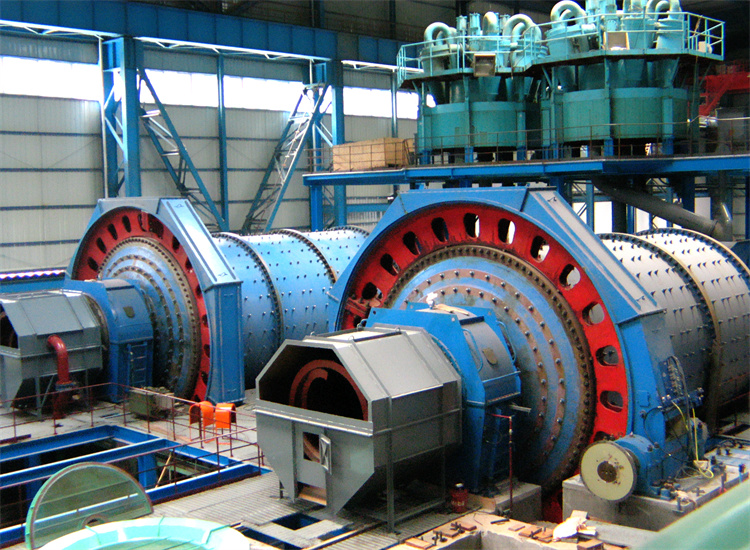

After crushing , comes grinding. We use ball mills. The aim is liberation. Gold particles are locked in rock. Grinding frees them. If gold is locked , cyanide cannot touch it. Recovery drops. This is a huge loss.

Ball mills rotate. Steel balls inside drop. They impact the ore. This is the cascading effect. Critical speed is a key factor. It is the speed where balls stick to the wall. Operating speed is usually 75% of critical. Why 75%. It gives the best impact force.

We look at Bond Work Index. It measures ore hardness. Harder ore needs more power. We calculate motor power based on this. SBM engineers calculate this precise. We check the liner wear too. Rubber liners last longer. They save money over time.

Output size is crucial. Usually 200 mesh. This is 74 microns. 80% passing this size is standard. If too coarse , gold stays hidden. If too fine , slimes cause problems.

Leaching happens in big tanks. We use Carbon in Leach (CIL). Or Carbon in Pulp (CIP). The slurry flows into tanks. Agitators keep solids suspended. If solids settle , leaching stops. The impeller design matters. Double impellers are good. They mix better.

Air is blown in. Oxygen is needed for the reaction. Sometimes we use pure oxygen. It speeds up the process. Reaction time is 24 hours often. Sometimes 48 hours. It depends on the ore.

Activated carbon is added. It looks like black sand. It absorbs the dissolved gold. The carbon moves counter-current. This means opposite to slurry flow. Fresh carbon meets tailing slurry. Loaded carbon meets fresh slurry. This maximizes recovery. Why do we do this. It keeps the concentration gradient high.

Data from Mining Journal shows trends. CIL is better for preg-robbing ores. CIP is good for simple ores. We choose based on tests.

Before leaching , we thicken. Thickeners remove water. They increase solid density. Usually to 40% or 50%. Why increase density. It reduces tank volume needed. It saves cyanide usage. Less water means less chemical waste.

SBM uses efficient thickeners. The rake lifts automatically. This prevents bogging. Flocculants are added. They clump particles together. Settling is faster. The overflow water is clean. We recycle it. This saves water costs.

| Parameter | Standard Thickener | High-Rate Thickener |

|---|---|---|

| Solid Loading (t/m²/d) | 2.5 – 3.0 | 5.0 – 8.0 |

| Underflow Density (%) | 35 – 40 | 45 – 55 |

| Flocculant Use (g/t) | 10 – 20 | 5 – 10 |

Let us look at a real job. The location was Sudan. The climate is hot. Desert conditions. The ore was quartz vein. Gold grade was 5 g/t. The customer wanted high recovery.

The problem was hardness. The rock was very hard. Bond Index was 18 kWh/t. Standard mills failed. They wore out fast. Production stopped often. The client was angry. Money was lost.

SBM designed a solution. We utilized a wet grid ball mill. We changed the liners to high-manganese steel. We adjusted the ball charge ratio. We added more large balls.

The result was good. Availability went up to 95%. Recovery rate hit 93%. The client said: “SBM solved our headache. The mill runs smooth now.” Maintenance time dropped. Profits increased.

Another project was in Tanzania. It was a CIL plant. The ore had clay. Clay is sticky. It causes viscosity issues. Gold does not dissolve well. The slurry was too thick.

SBM engineers visited. We tested the slurry. We changed the thickener type. We utilized a deep-cone thickener. It handles clay better. We also optimized the carbon screen. It stopped clogging.

Installation took 4 months. Our team stayed on site. We trained the workers. The local team learned fast. The plant now runs stable. Reagent consumption dropped 15%. This is a big saving. Why did it drop. Better density control meant less water to treat.

Money matters most. You want a return. We do not list exact prices here. Prices change. Steel costs change. But we look at ROI.

Energy is a big cost. Crushing uses less energy than grinding. Efficient blasting helps. If rock is small before crushing , you save money. This is “Mine-to-Mill” strategy.

Reagents are ongoing costs. Cyanide is expensive. Lime is cheap but used a lot. Precise dosing saves cash. Automatic dosers pay for themselves. They stop waste. SBM automation helps here.

Good equipment needs good setup. Foundations must be strong. Vibrations kill machines. We pour concrete carefully. We check levels with lasers.

Maintenance is life. Bearings need grease. Belts need tension. We give a manual. It lists all parts. It tells when to change oil.

After-sales is vital. Machines will break eventually. You need spares fast. SBM keeps stock. We ship quick. Downtime is the enemy. We fight downtime.

1. Why is the gold recovery low?

Low recovery has causes. Maybe grind size is too coarse. Gold is not free. Maybe cyanide is low. Check the dosing. Maybe “preg-robbing” carbon is in ore. This natural carbon steals gold. You need CIL for this. Test your ore first. SBM lab can find the cause.

2. How do I control cyanide safety?

Cyanide is dangerous. You must control pH. Keep it above 10.5. Use sensors. Install gas detectors. Train your staff. Have antidotes ready. Safety drills are must. SBM provides safety training modules. Never ignore safety rules.

3. Can I process sulfide ores with this?

Sulfides are tricky. They consume cyanide. They enclose gold. Direct cyanidation works poorly. Recovery is low. You need pre-treatment. Roasting is one way. Bio-oxidation is another. Flotation can concentrate gold first. Then leach the concentrate. This saves tank size. Ask SBM experts for a flow chart.

Gold cyanidation is powerful. It needs right machines. It needs process control. You must understand your ore. Do mineralogy tests first. Do not guess.

Select equipment on quality. Not just price. Cheap machines break. They stop your cash flow. Look for heavy duty specs. Look for good liners.

Partner with experience. We have built hundreds of mines. We know the pitfalls. We help you avoid them. Contact us for your mine design.

Whatsapp:+8617329420102

Email: [email protected]

Address: No. 1688, Gaoke East Road, Pudong new district, Shanghai, China.

Online Service : Get Price

We value your feedback! Please complete the form below so that we can tailor our services to your specific needs.