Iron ore is tough. Very tough. Dealing with hard rocks like magnetite or hematite is hard work. Many crushers fail quickly. They wear out. They stop working. But the hydraulic cone crusher is different. It is the best choice for this job. This article explains why. We look at the tech. We look at real cases. We show you how SBM helps miners win.

Iron ore is heavy. It is abrasive. On the Mohs scale it is often 5.5 to 6.5. Sometimes harder. This means it eats metal liners. Standard crushers cannot handle it. They break. The stress is too high. You need a machine that fights back. A machine with power.

If you use a jaw crusher it is okay for the first step. But for the second step you need fine rocks. You need small stones. The hydraulic cone crusher does this best. It uses a special crushing force. It breaks rock against rock. This is called lamination crushing.

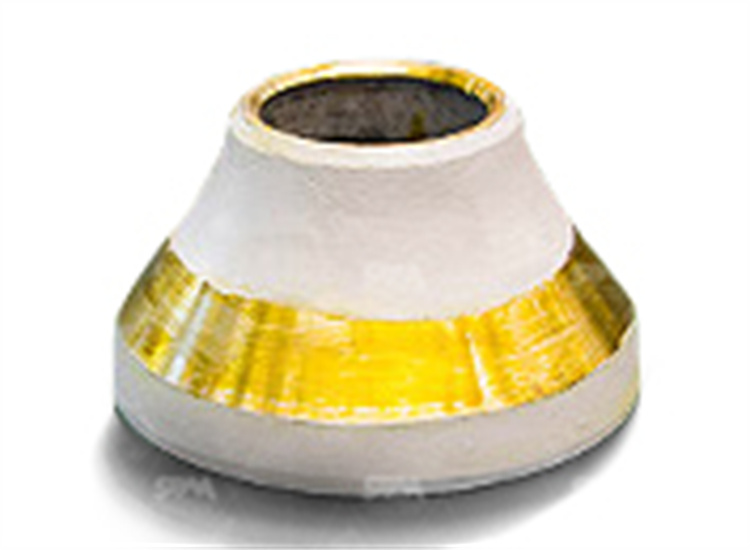

The hydraulic cone crusher has a moving cone. This is the mantle. It spins inside a fixed cone. This is the concave. The gap between them changes. Rocks fall in. They get squeezed. They break.

We need to know two terms. One is CSS. This stands for Closed Side Setting. It is the smallest gap. It decides the size of the final product. The other is OSS. Open Side Setting. This is the biggest gap. It lets material in.

Why this matters:

According to data from the Minerals Engineering journal high pressure improves the shape. It makes cubes. Not needles. Cubes are better for grinding mills. They grind faster.

This is a big pain point. Iron ore acts like sandpaper. It rubs the steel away. If you use a spring cone crusher you suffer. The pressure is uneven. The rocks slip. This causes rubbing. Rubbing kills liners.

The Solution:

The hydraulic cone crusher fills the chamber. This is choke feeding. We keep the head full of rocks. The rocks crush each other. This is lamination. Less rock touches the metal. The wear is slower. SBM tests show this doubles liner life. You save money on parts. You stop less often.

Sometimes a metal tooth falls in. Or a rock is too big. In old machines you stop. You dig it out by hand. This takes hours. It is dangerous. You lose production. This is bad for business.

The Solution:

Hydraulic cylinders act fast. They sense the pressure spike. They lower the mantle instantly. The opening gets big. The blockage drops out. Then it resets. It takes seconds. Not hours. This is automatic clearing.

Why: The hydraulic system is like a fuse. It protects the main shaft. It prevents the machine from breaking.

Let us look at the numbers. We compare a standard spring crusher with a multi-cylinder hydraulic one. The difference is clear. SBM uses these specs for design.

| Feature | Spring Cone Crusher | Hydraulic Cone Crusher |

|---|---|---|

| Crushing Force | Low | High (Inter-particle) |

| Pass through capacity | 100% (Baseline) | 135% (Higher) |

| Product Shape | Flaky / Flat | Cubic (Good) |

| Clearing Time | 2-4 Hours | 10 Minutes |

| Automation | Manual | PLC Controlled |

We worked on a site in Western Australia. The climate was hot. 45 degrees Celsius. The ore was Magnetite. Very hard. The client used old crushers before. They broke every week. The main shaft snapped.

The SBM Solution:

We installed the H-Series Multi-cylinder Hydraulic Cone. Model H-400. We set the CSS to 12mm. The motor power was 315kW. We added a heavy-duty air cooler for the oil. Because of the heat.

The Result:

The client was happy. “The machine just runs,” said the Site Manager Dave. “We do not touch it.” Production went up by 40%. The liner lasted 600 hours. Before it was 300 hours. The energy use per ton dropped. It dropped by 15%.

This was in the Andes. 3500 meters high. The air is thin. Motors get hot easily. The ore was mixed copper and iron. It was sticky. Sticky ore packs the chamber. It stops the machine.

The SBM Solution:

We used a Single Cylinder Hydraulic Cone. It has a steep cavity. The rocks fall fast. Gravity helps. We used a larger motor to handle the thin air. We integrated a smart PLC system.

The Result:

The blockage issue stopped. The PLC watched the pressure. If pressure went high it opened the gap a little. Just for a second. The sticky mud passed through. No stopping. The daily output hit 2000 tons. The client recovered the cost in 6 months.

A good machine needs good care. Do not ignore the basics. Installation is key. The foundation must be flat. It must absorb vibration. Use concrete. Use rubber pads.

Maintenance Checklist:

Why: Dirt in oil ruins the bronze bearings. This is the number one killer of cone crushers.

Do not just buy the biggest one. That is a mistake. You must match the rest of the plant. Look at your jaw crusher. What size rock does it give?

If the feed is 200mm you need a large intake. If the feed is 50mm you need a fine head. SBM engineers calculate this. We use a flow chart. We balance the stages. Stage 1 flows to Stage 2. The speeds must match.

Yes you can. But you must be careful. The hydraulic cone is better than the spring type. The clearing stroke is huge. It lets mud pass. However do not exceed 5% moisture if possible. Or wash the ore first.

It saves a lot. The crushing efficiency is high. You crush more rock per kilowatt. Usually it is 15-20% better than old spring crushers. The motor works hard but the work is useful. It does not waste energy shaking the ground.

No it is simple. SBM sets it up. You see a touch screen. You see buttons. Green is good. Red is bad. You can see the oil temp. You can see the amp draw. It is like a phone. Very easy for operators.

The hydraulic cone crusher is the king of hard rock. It is strong. It is smart. It saves you money on wear parts. For iron ore you have no better choice. It handles the stress. It gives you good cubes.

Stop wasting time with old machines. Upgrade to hydraulic. Your mine deserves it. Trust SBM to help you select. We know mining. We know equipment.

Whatsapp:+8617329420102

Email: [email protected]

Address: No. 1688, Gaoke East Road, Pudong new district, Shanghai, China.

Online Service : Get Price

We value your feedback! Please complete the form below so that we can tailor our services to your specific needs.