Lithium mining faces a big problem . The problem is high dilution rate. Waste rock like amphibolite enters the mill. This increases energy cost . It also lowers recovery rates. Early sorting is the solution. This article explains how to remove waste rock. We focus on crushing and sizing . Read this to optimize your mine.

Lithium ore grade is usually low. It is often 1.0% to 1.5% Li2O. This means 98% is waste. Transporting waste is expensive . Grinding waste uses much electricity. Minerals Engineering journal states a fact. Pre-concentration can reject 30% of waste mass.

This increases the feed grade. It stabilizes the flotation plant. Why ? Because less gangue enters the cells. The chemical usage drops . Water recovery improves. Therefore , sorting is vital. It is not just an option. It is a necessity for profit.

Sorting separates valuable rock from waste. It uses physical properties. These are color , density , or conductivity. For lithium , we often use XRT. XRT stands for X-Ray Transmission. It sees atomic density.

Spodumene has different density than quartz. But sensors have a limit. They need specific particle sizes. The rock must be 10mm to 50mm. If rocks are too small , sensors miss them. If rocks are too big , separation is poor.

To get 10-50mm rock , we need crushers. We do not want fine powder yet. Powder cannot be sorted easily. So , we choose crushers carefully. We avoid over-crushing.

Primary Crushing: Jaw Crusher We use the SBM PE Jaw Crusher. It uses a toggle plate mechanism. The motor drives the belt. The movable jaw squeezes the rock.

Parameter: Reduction Ratio. It is usually 4:1 to 6:1.

Why? To break 500mm boulders down quickly.

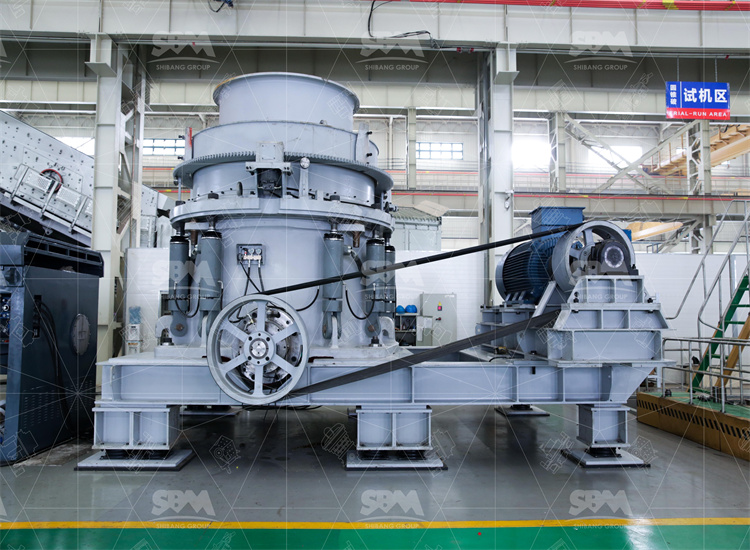

Secondary Crushing: Cone Crusher We use SBM HPT Hydraulic Cone Crusher. It creates a good shape. The shape is cubic.

Parameter: CSS (Closed Side Setting).

Why? It controls the final output size. We set it to 18mm or 20mm.

No , you cannot. This is a common mistake. Some crushers make too many “fines”. Fines are particles under 5mm. Sensor sorters cannot handle fines well.

Impact Crushers? They create too much powder. They hit the rock hard. This is bad for pre-concentration.

Cone Crushers? They use lamination crushing. Rock breaks rock. This preserves the crystal structure. It produces less dust. Therefore , SBM recommends cone crushers for this stage.

Background The mine is in Western Australia. The ore is hard spodumene. The compressive strength is 200 MPa. The climate is hot and dry.

Equipment List SBM PE-900×1200 Jaw Crusher.

SBM HPT-300 Cone Crusher.

Vibrating Screen (3 decks).

The Challenge The client had high iron contamination. The amphibolite was mixing with lithium. The mill grade was only 0.9%.

The Solution We installed the crushing circuit. We set the screen to cut at 12mm. The fraction 12mm-45mm went to XRT sorters. The fraction 0-12mm went to DMS.

Result The waste rejection was 40%. The feed grade to mill rose to 1.6%. The client said : “The SBM crushers are robust. The particle shape is perfect for the sensors.”

The CSS determines the product curve. CSS stands for Closed Side Setting. It is the smallest gap in the crusher.

If CSS is 15mm , most rocks are smaller than 20mm. However , some oversize exists. You must check the “Open Circuit” vs “Closed Circuit”.

Closed Circuit Oversize rocks return to the crusher. This ensures 100% passing size.

Benefit: Uniform feed for sorting.

Drawback: Higher circulating load.

| Size Fraction (mm) | Passing % | Suitability for Sorting |

|---|---|---|

| 0 – 5 mm | 15% | Poor (Too fine) |

| 5 – 15 mm | 35% | Good (DMS) |

| 15 – 40 mm | 40% | Excellent (XRT) |

| > 40 mm | 10% | Recycle needed |

Many miners ask this . The answer is often waste rock. You are grinding rocks with zero value.

The Calculation Bond Work Index (Wi) for Spodumene is 14-16 kWh/t. Waste rock (Basalt/Amphibolite) can be 18-20 kWh/t. Waste is harder than ore.

If you remove 30% waste early , you save energy. You save more than 30% power. Because you remove the hardest rocks. This is simple physics. SBM engineers calculate this for every client.

Background A project in Zimbabwe processes Lepidolite. The target capacity is 200 tph. The ore contains mica and quartz.

The Pain Point The crushing plant was old. It broke down often. The output size was irregular. The manual sorting was inefficient.

SBM Solution We replaced the secondary crusher. We used a SBM HST Single Cylinder Cone Crusher. It has automated control. It adjusts the gap automatically.

Operational Data Feed Size: 0-500mm.

Product: 10-60mm for sorting belts.

Availability: 98% uptime.

Customer Feedback “The HST cone is smart. We touch a button to adjust. The maintenance is very low. We removed 40 workers from sorting. The machine does the work.”

Good equipment needs care . SBM provides detailed manuals.

Installation Tips Foundation: Concrete must be cured . Vibration is heavy.

Alignment: Motor and pulley must align. Misalignment kills belts.

Why? To stop energy loss and heat.

Maintenance Check Check the liner wear daily. If liners are worn , settings change. The CSS increases. The product gets bigger. Sorting efficiency drops. Replace liners when 50% worn.

1. Know your mineral. Is it Spodumene or Lepidolite?

2. Test the crushability. What is the Bond Index?

3. Define sorting size. Usually 10mm to 50mm.

4. Select SBM crushers. We match the motor power accurately.

Do not buy oversized motors. It wastes money. Do not buy undersized motors. They stall under load.

Q1: Does ore sorting waste lithium? A: A small amount is lost . Maybe 2-3% of lithium. But the grade increases largely. The economic gain outweighs the loss. It is a trade-off. We calculate the ROI for you.

Q2: Can SBM crushers handle wet ore? A: Yes , but be careful. If moisture is >5% , fines stick. We recommend screening first. Remove the mud before crushing. This protects the liner profile. It prevents packing.

Q3: What is the lead time for SBM equipment? A: We have stock for standard models. Models like PE-600×900 are ready. Custom voltages take longer. Usually 30 days. We ship globally from Shanghai. Our logistics are fast.

Whatsapp:+8617329420102

Email: [email protected]

Address: No. 1688, Gaoke East Road, Pudong new district, Shanghai, China.

Online Service : Get Price

We value your feedback! Please complete the form below so that we can tailor our services to your specific needs.