Find a proven gravity or flotation unit, check real operating specs, verify test-data, and choose a supplier with field service. This short guide shows practical tests, clear specs, and selection rules that reduce risk.

A gold ore separating machine is a processing unit that isolates heavy aurum particles from gangue. Buyers often confuse name-plates with real performance. Therefore, verify feed size, throughput, and recovery on site, not only on paper. Poor sourcing causes low recovery, high wear, and costly downtime; consequently your margin shrinks fast.

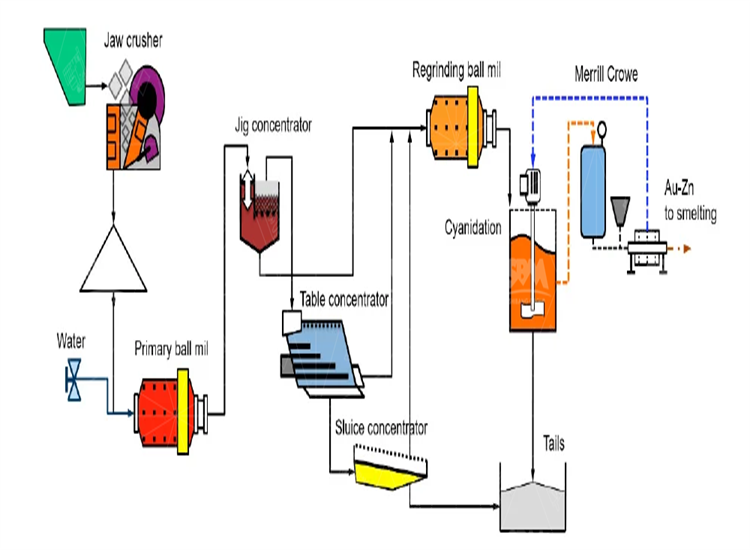

Gravity concentration uses density difference and motion. Centrifugal concentrators add G-force to boost fine recovery. Shaking tables sort by flowing film and riffles. Jigs use pulsation and hindered settling. Flotation cells use reagents to attach fine gold to air bubbles. Each method has limits on feed size and throughput, so match method to ore.

Do not buy without these numbers: feed particle size distribution, product size, throughput (t/h), motor power (kW), rotational speed (rpm) or G-force, conc. ratio, and typical recovery percent. For crushers ahead of separators, note CSS/OSS, chamber profile, reduction ratio and matched motor torque. Energy for comminution dominates plant use, so factor it in.

Ask for test reports and mass balance. Request a stamped PSD (particle size distribution) of feed. Confirm drive sizing matches torque curves. Check cleaning cycles and maintenance intervals. Validate reported recovery with a split-sampling test. Demand power draw curves under load. If a supplier refuses tests, walk away.

Match machine to these conservative windows. Centrifugal concentrators: feed 0–6 mm, typical working feed 65% ≤0.074 mm for fine recovery, capacity 0.5–60 t/h per unit depending on model. Shaking tables: best for 0.02–2.0 mm ranges, capacities often 0.5–2 t/h per table. Jigs: feed up to 25–30 mm, capacity 1–25 t/h. These ranges guide preliminary selection.

Use the table to compare candidate units. Replace generic labels with supplier test numbers. If numbers diverge strongly, require plant trials.

| Unit type | Feed size | Capacity (t/h) |

|---|---|---|

| Centrifugal concentrator | 0–6 mm (opt 0–0.2 mm) | 0.5–10 |

| Shaking table | 0.02–2.0 mm | 0.5–2.0 |

| Jig concentrator | <25 mm | 1–25 |

Collect these run-time metrics: specific energy kWh/t, monthly availability %, mean time between failures (MTBF), mean time to repair (MTTR), spare parts list, and scheduled maintenance hours. Industry surveys show comminution consumes the majority of processing energy; therefore you should aim to minimize over-grinding.

Require onsite commissioning, training, and spare parts. Insist supplier supply assembly drawings, electrical one-line, and lubrication schedules. Set warranty KPIs: availability >92%, response time <48h, and defined spare kits. Simple things save weeks later; for example correct belt tension and rotor balancing cut vibration and wear.

Project background: river-placers, clay and sand matrix, seasonal water variance. Design: two centrifugal concentrators in parallel, one shaking table polishing stage, cyclone classification. Feed: 0–6 mm, with 70% less than 0.15 mm after screening. Outcome: recovery rose from 68% to 89% after retrofits. Issues solved: lost fines in sluice, excessive rotor wear. Client feedback: onsite training by Shanghai SBM shortened start-up to 3 days and reduced spare rotor lead time.

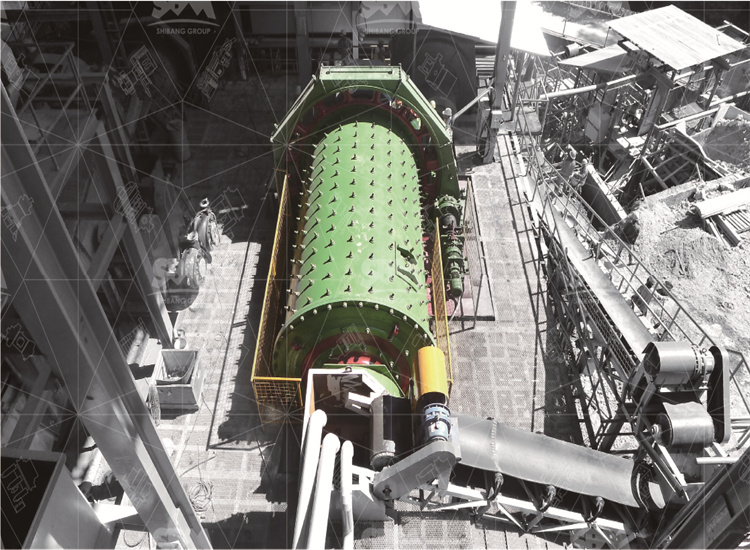

Project background: refractory sulfide ore, hard rock, low head grade. Design: primary jaw crusher, secondary cone crusher with CSS set to 6 mm, closed-circuit ball mill to 75 μm, then shaking table and flotation scavenger. Result: improved concentrate grade by 22%, lowered tailings grade, and cut reagent consumption after optimization. Customer note: Shanghai SBM provided matched motor selection and torque curves. Commissioning reports were signed off after split sample validation.

Step 1: ask for test certificates. Step 2: request plant references with contactable engineers. Step 3: inspect a working unit. Step 4: require FMEA on critical parts. Step 5: sign performance guarantee tied to recycling tests. This sequence reduces buying junk.

Do not over-promise returns. Use mass balance to estimate upgraded ounces per hour. Compute simple payback based on increased recovery and operating costs. Include spare rotor, liners, and wear parts in initial CAPEX. Conservative modelling avoids unpleasant surprises.

Ensure foundation notes, alignment tolerances, earthing, and anti-vibration mounts are included. Verify lubrication intervals, rotor balancing reports, and replaceable wear part lead times. Plan annual shutdown windows for full inspection.

Q1: How to verify recovery claims? Run the supplier’s unit with your feed. Insist on split sampling and an independent assayer. Do mass balance across head, concentrate and tail. If supplier resists, treat claims as marketing only.

Q2: Which unit lowers operating cost? Gravity units usually use less reagent and less power than flotation. However, for sub-micron gold, flotation plus fine grinding gives better liberation. Match method to particle size distribution.

Q3: What maintenance items fail most? Rotors, bearings, and liners fail first. Balanced rotors and correct lubrication extend life. Keep spare kits for these parts in stock.

1) Confirm PSD and plant mass balance. 2) Request site demo. 3) Verify motor torque and power curves. 4) Get MTBF data and spare list. 5) Tie payment to performance tests. Follow this and you will avoid low-grade junk.

Sourcing is simple when you rely on measured data, not glossy specs. Use the checklists above. For field tested units, ask Shanghai SBM for demo dates, factory acceptance tests, and service contracts. Investing time now prevents months of lost revenue later.

Whatsapp:+8617329420102

Email: [email protected]

Address: No. 1688, Gaoke East Road, Pudong new district, Shanghai, China.

Online Service : Get Price

We value your feedback! Please complete the form below so that we can tailor our services to your specific needs.