This guide compares gravity and flotation routes for gold recovery, explains core equipment and parameters, and gives tested selection advice,; backed by field records and SBM project feedback.

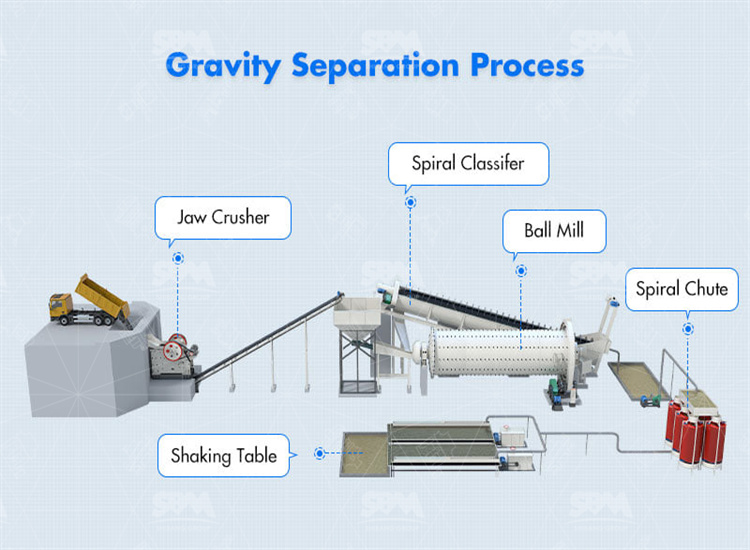

Gravity separation uses density difference to concentrate gold. Particles fall, segregate, and are captured by physical devices. Flotation separates minerals by surface chemistry, reagents and air bubbles attach to target particles, lifting them as froth. Both methods often follow comminution. Therefore, correct upstream crushing and grinding controls feed size and recovery.

Jaw, cone and impact crushers reduce ROM ore. Typical crusher reduction ratio is 4:1 to 6:1. For cone crushers, CSS (closed side setting) often ranges 6–30 mm, depending on chamber type. OSS (open side setting) and eccentric speed affect product curve. For SAG/ball mills, mill speed is set at 65–80% of critical speed. Motor power matched to torque requirement; e.g., a 1.5 MW mill usually supports 50–150 tph, depending on ore hardness. Moreover, feed size to gravity devices typically must be minus 6 mm, while flotation prefers minus 150 μm in many gold circuits.

Common machines: sluice boxes, centrifugal concentrators (e.g., Knelson, Falcon), shaking tables, jigs, and spiral concentrators. Centrifugal concentrators operate at bowl G-forces between 40 g and 200 g. Feed size range is often 0.074–6 mm. Throughput varies: small concentrators treat 0.5–5 t/h, larger units treat 10–50 t/h. Key metrics: cut point, feed feed rate, pulp density, recovery percentage, and motor power. For example, a Knelson-type concentrator used in a 20 t/h feed can achieve 85–95% coarse-gold recovery when pre-crushed to -3 mm. Energy consumption is low relative to milling; typical device motor power ranges 1.1–15 kW. Maintenance interval often 500–2000 operating hours, depending on abrasivity.

Flotation uses mechanical or column cells. Mechanical cells mix air, reagents and pulp using impellers. Column cells provide gentler aeration, higher grade concentrates, and lower power per m3. Typical cell volumes range 0.5–50 m3. Impeller speed, aeration rate, and froth depth control selectivity. Pulp densities are usually 30–40% solids for gold flotation, but vary with ore. Reagent dosing, including collectors, frothers, and modifiers, is critical. Recovery vs grade trade off must be tested at pilot scale. Power draw for flotation banks may be 20–120 kW per cell bank, depending on size and number.

First determine ore type: free-milling or refractory. Secondly, test liberation size and gold association. If gold is coarse, gravity-first often wins. If gold is locked in sulfides, flotation or pre-oxidation is needed. Finally, combine methods: gravity scavenging ahead of flotation improves economics. Below is a simple particle size vs route table.

| Feed d50 | Preferred Route | Typical Recovery |

|---|---|---|

| -3 mm | Gravity + leach | 70%-95% |

Capacity examples: gravity concentrator trains treat 1–100 t/h per line. Flotation trains treat 10–1000 t/h. Feed and product sizes must align; gravity needs coarse feed, flotation needs fine feed. Energy: coarse gravity circuits consume <10 kWh/t for the capture stage. Grinding and flotation often dominate energy, e.g., 15–35 kWh/t for fine grinding plus 1–5 kWh/t for flotation. Reported field fault rates vary, yet reliable SBM equipment shows typical mechanical fault incidence below 3% per year under standard maintenance. Maintenance cycles: minor checks monthly; major overhaul 12–36 months.

Step 1: characterize ore density, hardness (Bond ball mill work index), and liberation. Step 2: select primary crusher with suitable reduction ratio. Step 3: size mill to produce target P80. Step 4: choose concentration device by particle size and expected throughput. Example calc: For 50 t/h feed, desired P80 150 μm, Bond work index 13 kWh/t, mill power estimate = (Wi * Q * (10/√P80 – 10/√F80))/ (10) — use pilot values; adjust for efficiency. Meanwhile, plan reagent consumption, tailings handling, and water balance. Monitor cut point and adjust feed rates, rpm, or air rates accordingly.

Install units on concrete pads with anti-vibration mounts. Ensure correct belt alignment, proper oil levels, and protective guards. For centrifugal concentrators, check bowl wear liners every 500 hours. For flotation cells, inspect impeller clearances weekly. Schedule predictive maintenance by vibration analysis, and keep spare parts kits for bearings and seals. Train operators for routine adjustments; moreover, log daily performance to detect drift. SBM offers commissioning support, and operators report quick ramp-up when training is included.

Situation: coarse free gold in a placer deposit. Ore: alluvial sand with gold particles 0.5–10 mm. Climate: seasonal wet, cold winters. Design: feed pre-screened at -10 mm, primary wash plant, two-stage gravity train with spirals and Knelson concentrators, tailings dewatering. Equipment list: 2 x jaw crushers, 1 x trommel screen, 3 x spiral concentrators, 2 x centrifugal concentrators, 1 x shaking table. Results: coarse gold recovery reached 92% in first six months. Energy use was low; average 6 kWh/t for separation. Client feedback: operators praised simple maintenance and robust design,; they noted quick spare parts delivery from SBM.

Situation: refractory gold associated with sulfides. Ore hardness: high, Bond index 15 kWh/t. Design: primary crushing, SAG milling to 80 μm, gravity scavenging ahead of flotation, flotation on sulfide concentrates followed by roasting and leach. Equipment: 1 x SAG mill (2.5 MW), 2 x ball mills, 4 x centrifugal concentrators for scavenging, 6 x mechanical flotation cells, reagent dosing skids. Outcome: combined recovery increased from 68% to 86% after installing gravity ahead of flotation. Client commentary: installation ran on schedule; routine maintenance intervals matched design. SBM field engineers optimized reagent feed and reduced reagent consumption by 12%.

First, feeding fines to gravity devices will reduce recovery dramatically. Second, under-sizing flotation cells causes short-circuiting and low grade. Third, ignoring water chemistry raises reagent consumption. Therefore, always run locked-cycle tests. Also, do field trials before full-scale purchase. Use pilot units to validate mass balance and kinetics.

A1: Choose gravity-first when gold is coarse or liberated above 150 μm. Also choose it to reduce downstream loads and chemical use. Tests show gravity-first lowers flotation load by 20–50%.

A2: Determine target cut size, then select bowl size and rpm. For 30 t/h fine feed, use multiple small concentrators in parallel. Confirm with pilot runs, and match feed solids concentration to manufacturer specs.

A3: Major costs: grinding energy, reagent, wear components, and labour. Gravity gear has low reagent costs but needs wear parts. Flotation costs include reagents and cell power. Calculate net present value using your recovery uplift estimates.

In summary, gravity is efficient for coarse liberated gold. Flotation excels when gold is locked in sulfides. Combine both when needed. For selection, run ores tests, pilot the preferred flowsheet, then scale. Engage experienced suppliers early. SBM technical teams can supply pilot units, commissioning and training; clients report measurable gains, and stable operations after commissioning.

Whatsapp:+8617329420102

Email: [email protected]

Address: No. 1688, Gaoke East Road, Pudong new district, Shanghai, China.

Online Service : Get Price

We value your feedback! Please complete the form below so that we can tailor our services to your specific needs.