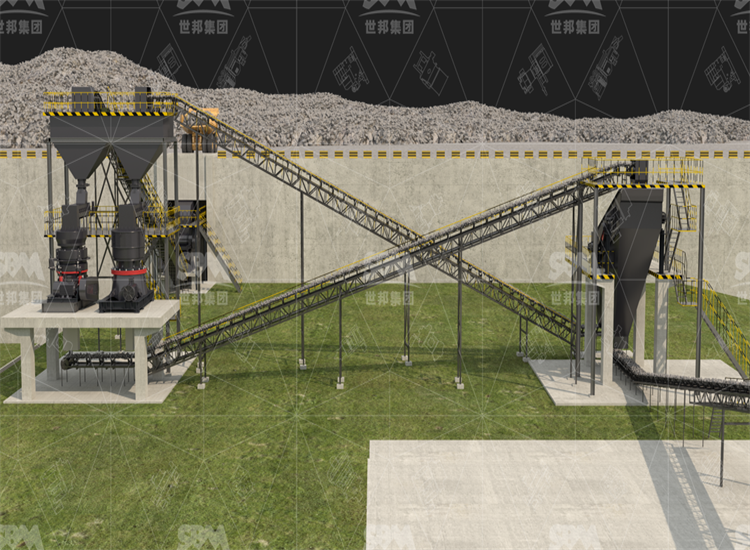

Many investors love turn-key projects. You pay money. You get the key. You start the mine. It sounds perfect. It sounds easy. But reality is often different. We see many failed projects. Why do they fail. The risks are hidden. They are under the surface. You must know these risks. If you do not know, you lose money. We are SBM. We know these traps. We want to help you avoid them. This article explains everything. It is simple to read. Even a child can understand.

Many suppliers are lazy. They use one design for everyone. This is a big mistake. Every mine is different. Your rock is unique. The weather is unique. A design for soft limestone fails on granite. We must test the rock first. This is called the Bond Work Index. It measures hardness. It measures how hard to crush. If we ignore this, the machine breaks. The motor burns out. The capacity will be low. SBM always tests the rock. We check the abrasiveness too. High silica wears steel fast. You need special liners. A standard liner will die in a week. This is the first risk. Do not accept a copy-paste design.

The jaw crusher is the first step. It eats big rocks. It uses a toggle plate. This is a safety part. It protects the machine. If a steel piece enters, the plate breaks. The machine stops. It does not break the expensive shaft. But the angle is important. We call it the Nip Angle. It should be 18 to 22 degrees. Why. Because friction holds the rock. If the angle is too big, rock shoots up. It is dangerous. It kills capacity. If the angle is small, the rock crushes well. But the capacity drops slightly. We need balance. SBM calculates this perfectly. We adjust the CSS. That is Closed Side Setting. It controls the output size. We also check the OSS. That is Open Side Setting. These determine your flow.

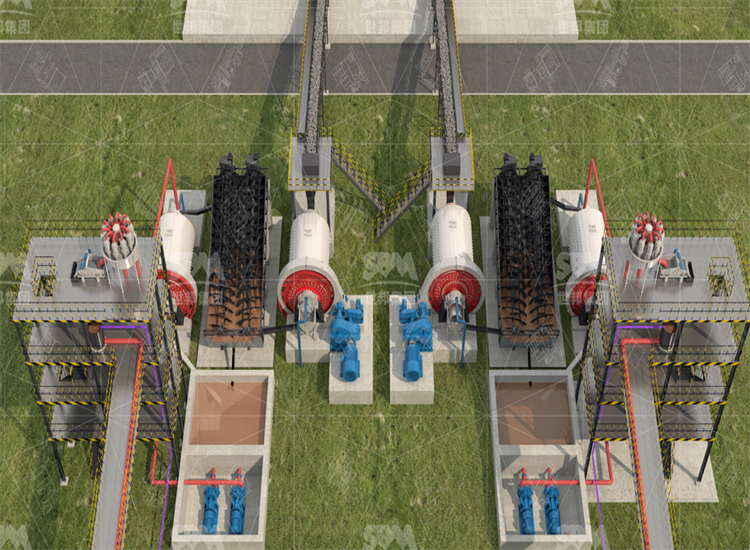

Power is money. Electricity costs are high. You do not want a huge motor. It wastes energy. But a small motor is weak. It stalls under load. We look at the crushing ratio. This is input size divided by output size. High ratio needs more power. We calculate the kilowatt demand. We use the formula from Taggart. It is an industry standard. We check the flywheel energy too. The flywheel stores energy. It helps the motor during hard peaks. SBM matches the motor to the flywheel. This creates smooth operation. The amps stay stable. Your bill stays lower. Many cheap factories guess the power. They guess wrong. Then you have downtime. Downtime kills profit.

This is a common question. You start the plant. It runs great. One month later, production drops 20%. Why. The answer is wear. The liners wear out. The gap gets bigger. The rock gets bigger. The secondary crusher works harder. It bottles up. The whole plant slows down. You must adjust the CSS regularly. Many people forget this. Also, check the voltage. Low voltage slows the motor. The slip increases. The RPM drops. We advise a weekly check. Measure the gap. Tighten the spring. SBM machines are easy to adjust. We use hydraulic assist. It takes ten minutes. Not hours. This keeps capacity high. It is simple maintenance.

Water is an enemy. Wet rock sticks. It clogs the chamber. We call it “packing.” The throughput stops. The pressure rises. The machine can crack. Do you have rain. Is the clay content high. If yes, you need a different feeder. A wobble feeder is good. It shakes the mud off. A standard grizzly feeder might fail. SBM checks your climate. We check the soil. We design for the worst day. Not the best day. If you ignore moisture, you will stop often. Workers must clean the chamber. It is dangerous work. It costs time. Always tell us about the rain. It changes the design completely.

Data tells the truth. We do not lie. Look at the numbers. This table shows the difference. We compare a cheap design with an SBM design. The material is Basalt. It is very hard. The input size is 600mm. The output is 20mm. See the power and wear life.

| Parameter | Standard Cheap Plant | SBM Optimized Plant |

|---|---|---|

| Energy Consumption (kWh/t) | 2.8 | 2.1 |

| Liner Wear Life (Hours) | 350 | 680 |

| Weekly Maintenance (Hours) | 12 | 4 |

| Fine Content (<5mm) | 35% | 22% |

Let me tell a story. A client in Abuja bought a cheap line. He wanted to save money. The rock was granite. It was very hard. Compression strength was 280 Mpa. The cheap jaw crusher broke its shaft twice. The bearings overheated daily. He called SBM for help. We visited the site. We saw the problem. The eccentric throw was too small. The crushing force was weak. We replaced the main unit. We installed an SBM PE-900×1200 Jaw Crusher. It has a heavy flywheel. It has deep jaws. The nip angle is optimized. The result was instant. Production went from 80 tph to 150 tph. The heat stopped. The client was happy. He said the SBM machine is a “beast.” He saved his contract.

No. Never. The initial price is just 20%. The operating cost is 80%. We call this OPEX vs CAPEX. CAPEX is what you buy. OPEX is what you spend to run. A cheap machine uses more power. It breaks often. You buy more parts. You lose production days. In two years, the cheap machine costs double. An SBM machine costs a bit more now. But it runs cheap later. The steel is better. It lasts longer. The bearings are Timken or SKF. They do not fail. Do not look only at the price tag. Look at the lifetime cost. Smart investors know this. They buy quality. They buy peace of mind.

Let us talk about the cone crusher. It is for the second stage. It shapes the stone. The cavity is the space inside. It matters a lot. There are many types. Standard, Medium, Short Head. Which one do you need. It depends on the feed size. If rocks are big, use Standard. If rocks are small, use Short Head. If you use the wrong one, efficiency drops. The rock bounces. It does not crush. We call this “bell mouth” wear. It ruins the liner. SBM engineers calculate the feed curve. We pick the right cavity. We ensure “choke feeding.” This means the head is full. Rock crushes rock. This makes good shape. It makes cubes. Not flakes.

Machines need power. Good power. Voltage fluctuation is bad. In many mines, power is unstable. It jumps up and down. This kills motors. It burns the insulation. Turn-key projects often ignore this. They give cheap panels. They have no protection. SBM uses Soft Starters. Or we use VFDs. Variable Frequency Drives. They start the motor slow. There is no spike. It protects the grid. It protects the motor. We also use thermal relays. If the motor gets hot, it trips. It saves the machine. We check your transformer too. Is it big enough. Many forget this. Then the lights dim when the crusher starts. It is a simple check. But it is vital.

We had a client in Luzon. He had river stone. It is very abrasive. It is round. Round stone is hard to grab. It slips. His old cone crusher made “needles.” The concrete mix was bad. The buyers rejected his stone. He was losing money. He asked SBM for a solution. We analyzed the stone. We suggested the HST Single Cylinder Cone Crusher. Why. Because it has high pressure. It uses a steep mantle. It crushes by lamination. This breaks the stone inside the stone. The shape becomes cubical. We installed it in two weeks. The product changed. It became perfect cubes. The concrete strength went up. His customers came back. He said SBM saved his business. He liked the PLC screen too. It was easy to use.

Buying is easy. Installing is hard. A bad foundation ruins a good machine. Vibration destroys concrete. We give detailed drawings. We show the rebar layout. We show the depth. SBM sends engineers to you. We watch the pouring. We level the frame. We use laser alignment. The belts must be straight. If not, they wear out fast. We train your workers. We teach them to listen. A happy machine sounds smooth. A sad machine bangs. We teach them to grease. Grease is life. We provide a checklist. Daily checks. Weekly checks. Monthly checks. We leave only when you are running smooth. This is our service. It is part of the SBM brand.

The screen sorts the piles. It is the cash register. If it works, you sell. If it plugs, you lose. The angle is key. Usually 18 to 20 degrees. The stroke matters too. We call it amplitude. If the stroke is small, rocks stick. If it is too big, rocks fly. They do not sort. SBM screens use exciters. They are strong. They do not break. We use rubber springs. They are quiet. They last long. Steel springs break often. We also look at the mesh. Is it steel. Is it PU. PU lasts longer. But it has less open area. We balance this for you. We calculate the ton per square meter. We ensure efficiency.

Yes. You can. Many mines are far away. There is no grid. A generator is fine. But you must size it right. The startup current is high. It is 3 to 6 times the running current. If the gen-set is small, it stalls. We calculate the total load. We add a safety factor. Usually 1.5 times the total power. We also advise on fuel storage. Diesel is expensive. We try to use gravity flow. It saves pumps. SBM helps you pick the right generator brand. We want steady power.

It depends. It depends on the rock. Granite is hard. Limestone is soft. For granite, maybe 300 to 500 hours. For limestone, maybe 1000 hours. It also depends on the steel. SBM uses high manganese steel. Mn18Cr2. It is tough. It gets harder as it works. This is called work-hardening. Cheap plates use Mn13. They wear fast. We also advise to rotate the plates. Flip them over. This doubles the life. We teach your team how to check wear profiles.

This is a good question. Business grows. You want more. We design for this. We leave space on the layout. We leave space for a bigger belt. We leave space for a second crusher. You do not need to rebuild everything. You just add a machine. We call this modular design. It saves money later. Some suppliers pack everything tight. Then you are stuck. SBM thinks about your future. We plan for 5 years ahead. Not just today.

Mining is tough. Risks are everywhere. The rock is hard. The weather is hot. But the profit is good. If you do it right. Do not fall for the turn-key trap of cheap suppliers. They hide the risks. They hide the weak motors. They hide the bad steel. SBM is different. We are honest. We show the data. We test the rock. We design for you. Only for you. We are with you from the start. We are with you when you sell the stone. Choose wisdom. Choose experience. Choose SBM. Let us build a safe project together. Contact us today. We are ready.

Whatsapp:+8617329420102

Email: [email protected]

Address: No. 1688, Gaoke East Road, Pudong new district, Shanghai, China.

Online Service : Get Price

We value your feedback! Please complete the form below so that we can tailor our services to your specific needs.