Feldspar is everywhere. It is in glass. It is in ceramics. But you must crush it first. This is hard work. Feldspar is hard rock. It wears down machines. We know this well. SBM has fixed these problems for years. This guide tells you how. We show you the machines. We show you the data. We keep it simple.

Feldspar is a mineral group. It makes up 60% of the Earth’s crust. It is hard. Mohs hardness is 6 to 6.5. This is important. Hard rocks break weak crushers. You need strong steel. We crush it for two main things. Glass and ceramics. The size matters. Glass needs sand. Ceramics needs powder.

The chemical part matters too. It has alumina. It has alkali. These help melt glass. But iron is bad. Iron makes glass dark. Our crushers help remove iron. How? By not adding more iron. We use special liners. This protects the stone.

The first step is big rocks. We use a Jaw Crusher. SBM makes the PE Series. It is a beast. The principle is simple. It acts like a mouth. One jaw stays still. One jaw moves. The rock falls in. The jaw squeezes. Snap. The rock breaks.

Here is a key term. CSS. It means Closed Side Setting. This is the gap at the bottom. It sets the output size. For feldspar set it to 100mm. Why? It prepares rock for the next step. Smaller rocks save energy later. This is smart mining.

Standard citations say the reduction ratio is 4:1. Or even 6:1. This means big rocks get 6 times smaller. SBM jaws use high manganese steel. This steel gets harder as it works. It resists the feldspar scratch. This saves you money.

Now the rock is medium size. We need small stones. We use a Cone Crusher. SBM HPT series is best here. It uses lamination crushing. What is that? It crushes rock against rock. Not just rock against metal. This makes better shapes.

The principle involves a mantle. It spins inside a concave. The gap changes. The rock gets squeezed. It falls. It gets squeezed again. It comes out small. We call this “inter-particle crushing”. Mining Engineering journal praises this method. It reduces needle shapes. It makes cubes.

Key param: Eccentric Distance. This is how far the mantle swings. A big swing means more power. SBM lets you adjust this. You can change speed too. Higher speed makes more sand. Lower speed makes gravel. You decide.

Why choose hydraulic?

It clears jams fast. If iron gets in the system opens. The iron drops out. The system resets. No stopping. No tools needed. This keeps production high.

Let’s look at a real job. A client in Spain. They make high-end tiles. They needed pure feldspar. No black spots. They had a problem. Old crushers added iron dust. The tiles looked bad. They called SBM.

Project Data:

Location: Valencia, Spain.

Material: Potassium Feldspar.

Capacity: 200 tons per hour.

Input Size: 600mm.

Output Size: 0-5mm sand.

The SBM Solution:

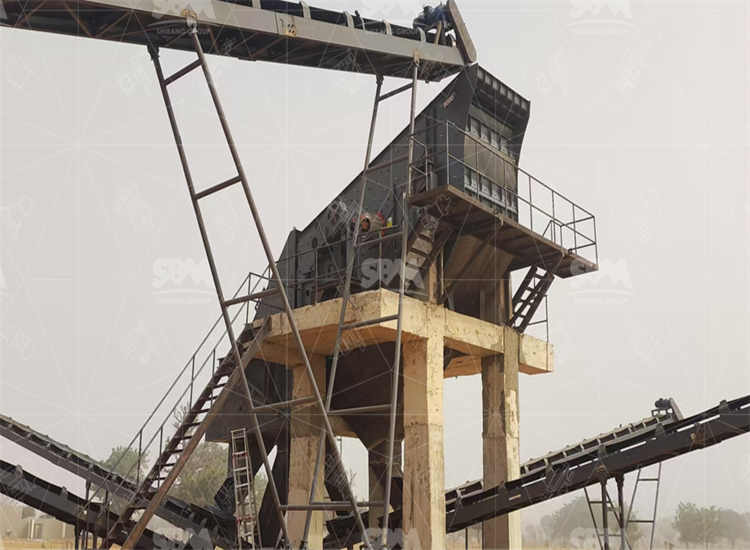

We designed a line. We used a PE750x1060 Jaw. Then a HST160 Cone. Finally a VSI6X sand maker. The cone used a special liner. The VSI used stone-on-stone. This reduced iron wear.

Client Feedback:

“The sand is clean,” said the plant manager. “We run 20 hours a day. The SBM cone crusher is stable. We change liners every 4 months. Before it was 2 months.” This is a win. They saved money on parts.

Yes you can. This is a common pain point. Many crushers make flat stones. Flat stones are weak. They break in concrete. They pack badly in glass melt. You need cubes. The answer is VSI. Vertical Shaft Impact.

The SBM VSI6X is the star. It is a centrifuge. It spins rock very fast. It throws rock against an anvil. Or against other rocks. We call this “Rock on Rock”. The impact breaks the sharp edges. It shapes the stone. It turns flat chips into cubes.

Why does this matter?

Glass melts faster with cubes. Concrete is stronger with cubes. You can sell cube sand for more money. The VSI adds value. It is the final polish.

Look at the numbers. Data does not lie. We compare machines here. This helps you choose.

| Machine Type | Feed Size (mm) | Output Size (mm) | Energy (kW/h) | Wear Cost |

|---|---|---|---|---|

| Jaw Crusher (PE) | Up to 1000 | 100 – 200 | Low | Low |

| Cone Crusher (HPT) | Up to 250 | 10 – 50 | Medium | Medium |

| VSI Crusher (5X) | Up to 50 | 0 – 5 | High | High |

This is the big question. Feldspar is abrasive. Silica content is high. It acts like sandpaper. If liners die fast you lose money. You stop the plant. You pay for parts. It hurts.

The Solution:

Check the material profile. Is the chamber full? A choke feed is best. This means the crusher is full of rock. Rock crushes rock. This saves the metal. If the crusher is half empty rock hits metal. This wears liners fast. Keep it full.

Also check the alloy. SBM uses high chrome for some parts. Manganese for others. Matching the steel to the rock is key. We help you do this. We test your rock first.

Another real story. A glass factory in Mexico. They need silica sand from feldspar. The market is hot. They needed speed. They had an old impact crusher. It made too much dust. Dust is waste.

The Fix:

We swapped the impactor. We put in a SBM VSI5X. We adjusted the rotor speed. We slowed it down just a bit. This controlled the break.

Results:

Dust went down by 30%. Usable sand went up. “The SBM machine paid for itself,” the owner said. “Installation was easy. The manual was clear.” They now produce 5000 tons a month. The motor is efficient. It uses less power per ton.

A good machine needs love. Treat it right. It lasts long. Here is what we know.

Foundation:

Concrete must be cured. Level it perfectly. If it vibrates it breaks. Use shock pads. SBM sends drawings. Follow them exactly.

Lubrication:

Oil is life. Check the temperature. If the oil is hot stop. It might be a bearing. Or dirt. Change oil filters often. Dust kills bearings. Keep the room clean.

Spares:

Keep a set of belts. Keep a liner set. Do not wait for a break. Order early. Downtime is the enemy. Smart managers plan ahead.

1. How do I control dust in the plant?

Feldspar makes white dust. It is bad for lungs. You must cover the conveyors. Use water sprays at drop points. But not too much water. It clogs screens. SBM sells dust collectors. They suck the dust away. It keeps the air clean. It meets safety laws.

2. Can I crush wet feldspar?

Be careful. A little damp is okay. Too wet is bad. Mud sticks. It blocks the jaw. It packs the cone. If moisture is over 5% dry it first. Or use a washing machine later. Do not crush mud. It breaks the machine.

3. How much power do I need?

It depends on the tons. For 100 tons per hour you need grid power. Generators are expensive. Check the voltage. Voltage drops hurt motors. We calculate the load for you. We check the start-up spike. We ensure your transformer is big enough.

We do not list prices here. Steel prices change. Shipping changes. But think about value. A cheap machine breaks. A good machine runs. SBM machines run for decades. The resale value stays high.

Think about:

Power cost per ton. Wear part cost per ton. Labor cost. SBM reduces all three. Automation helps. One man can run the plant. This is the real return on investment.

Crushing feldspar is science. You need the right tools. Do not guess.

Quick Decision Tree:

Big rocks? -> Use SBM Jaw.

Hard rocks? -> Use SBM Cone.

Need sand? -> Use SBM VSI.

Need cubes? -> Use SBM VSI.

We are SBM. We help you win. Contact us for a design. We check your site. We test your rock. We build your success.

Whatsapp:+8617329420102

Email: [email protected]

Address: No. 1688, Gaoke East Road, Pudong new district, Shanghai, China.

Online Service : Get Price

We value your feedback! Please complete the form below so that we can tailor our services to your specific needs.