Finding the right crusher is tough work. The market has many options. You need a machine that fits your specific rock type. If you process soft or medium-hard materials; you need efficiency. This guide helps you choose the best tool. We focus on low abrasion rocks. Examples are limestone coal and gypsum. We represent SBM. We provide honest technical facts here.

You must know your rock first. We use the Mohs scale for this. Soft rocks are rated 1 to 3. Medium-hard rocks are 4 to 5. Limestone usually sits at 3 or 4. Gypsum is softer at 2. Coal is also brittle.

Why does this matter? Hard rocks wear out steel fast. Soft rocks do not wear steel much. You do not need expensive cone crushers here. Impact style crushers work best. They use force and speed. They save you money on power. Do not buy oversized gear. It waste your budget.

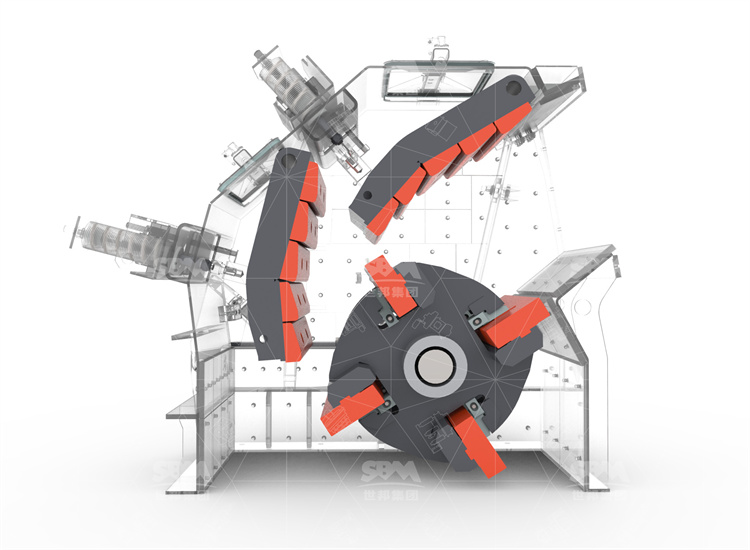

The Impact Crusher is the king here. SBM makes the CI5X series. It works on a simple principle. A heavy rotor spins fast. Blow bars hit the rock. The rock hits the curtain. It breaks instantly.

Key technical specs matter.

• Reduction Ratio: This is input size vs output size. Impact crushers offer high ratios up to 20:1.

• Rotor Speed: Higher RPM makes finer fines. Lower RPM makes coarse aggregate.

• CSS (Closed Side Setting): This sets the final gap. It controls the product size.

Why choose this? It shapes the stone well. The product is cubical. Concrete makers love cubical stone. Flat stone is bad for roads. SBM impact crushers ensure good shape. This adds value to your product.

Hammer crushers are old but good. They are great for coal. They are also good for soft limestone. The rotor has swinging hammers. They smash the rock against a grate.

The main benefit is “One-Step Crushing”. You can feed big rocks. You get small sand out. You do not need a secondary crusher. This saves capital cost. It simplifies the plant layout.

However; watch out for moisture. Wet clay clogs the grate. If your rock is dry hammer crushers are beasts. They are cheap to run. SBM hammer crushers have heavy rotors. This keeps inertia high. It saves motor energy.

Let us look at the numbers. Data is from SBM field tests. We compare the two types.

| Parameter | Impact Crusher (CI5X) | Hammer Crusher |

|---|---|---|

| Feed Size (Max) | 800mm | 1000mm |

| Reduction Ratio | Medium (15:1) | High (25:1) |

| Fines Content | Adjustable | High |

| Wear Part Life | High (on soft rock) | Medium |

| Moisture Tolerance | Good | Poor |

The table shows clear differences. Impact crushers are versatile. Hammer crushers are specialized. Choose based on your feed size. Also consider your moisture levels.

This is a common pain point. Users hate changing parts. If bars wear fast; check the silica content. Silica is abrasive. Impact crushers dislike silica. If silica is >10% switch to a cone crusher.

Another reason is rotor speed. Is it too fast? High speed increases wear friction. Slow the rotor down. It might save the steel. SBM uses high-chrome steel bars. They last longer than manganese. We solved this for many clients. A correct alloy selection is vital.

Yes you can. Many quarries lose money on dust. Dust is waste. To lower fines open the apron. Increase the CSS distance. This lets bigger stone pass through.

Also check the motor speed. Slow rotors hit softer. The rock breaks less violently. This keeps the stone size larger. SBM control panels allow speed shifts. You can tune this daily. It helps match market demand. Why make dust when you can make gravel?

Background: A quarry in Saraburi.

• Material: Medium limestone.

• Feed Size: 600mm.

• Goal: 250 tons per hour.

• Product: 0-5mm, 5-10mm, 10-20mm.

Solution: We installed an SBM PFW Impact Crusher. We added a vibrating feeder. The primary jaw was skipped. The PFW took large feed directly.

Result: The shape was perfect. Flakiness was under 8%. The client was happy. “We saved money on the primary jaw. The SBM impactor does it all. Maintenance is easy.” – Quarry Manager.

The power bill dropped 15%. This was due to the heavy rotor inertia. It kept momentum well.

Background: A power plant in Kalimantan.

• Material: Lignite coal.

• Moisture: 15% (High).

• Capacity: 500 tons per hour.

Solution: We avoided standard hammer crushers. The grate would clog. We used an SBM Ring Hammer Crusher. It has no bottom grate. Wet coal passes through.

Result: No clogging occurred. Production flowed smooth. “SBM solved our sticky coal problem. The machine runs 20 hours a day. No stoppages.” – Plant Engineer.

This proves proper selection matters. Design must match the environment.

Machines break. It is a fact. You need easy repairs. SBM designs for humans.

• Hydraulic Opening: Push a button. The machine opens. No cranes needed.

• Curtain Adjustment: Adjust settings hydraulically. It is safe and fast.

• Locking System: Safety locks protect workers.

Why is this critical? Downtime costs usually $1000 per hour. Saving 2 hours of repair time is huge. It pays for the machine. Smart design saves your wallet. Always look at access doors. Are they big enough? Ours are.

Price is not everything. Look at total cost.

• Purchase Cost: Impact crushers are cheaper than Cones.

• Operating Cost: Wear parts cost money.

• Energy Cost: Motors use electricity.

Impact crushers have low CapEx. If rock is soft; OpEx is also low. Your ROI is fast. Usually 6 to 9 months. Do not overspend on heavy iron. Use the right tool. SBM helps calculate this. We use decision trees. We map your rock to the profit model.

Q1: Can an impact crusher handle river stone? A: It is risky. River stone is hard. Silica is high. Wear parts will vanish fast. Use a Cone Crusher for river stone. Impact is for quarried limestone.

Q2: How often do I change blow bars? A: It depends on tons. For limestone; maybe every 3 months. For harder rock; maybe every month. Flip the bars to use both sides. This doubles the life.

Q3: What motor power do I need? A: It relies on tons per hour. Roughly 1 kW per ton. For 200 TPH use 200-250 kW. SBM engineers calculate this precisely. Do not guess.

Whatsapp:+8617329420102

Email: [email protected]

Address: No. 1688, Gaoke East Road, Pudong new district, Shanghai, China.

Online Service : Get Price

We value your feedback! Please complete the form below so that we can tailor our services to your specific needs.