Spodumene is the main source of lithium. The demand is high now. Batteries need it. But getting pure spodumene is hard. The rock is complex. Flotation is the best way to separate it. This article explains how we do it. We are SBM. We make the machines. We know the process. Here is the guide to spodumene flotation.

Spodumene has a similar surface to gangue. Gangue is waste rock. Usually quartz or feldspar. They float together. This is a problem. We need to change the water chemistry. We use specific chemicals. This makes spodumene float. The waste sinks. It sounds simple. But it is not. The mineral surface changes fast. Weathering hurts separation. Slime covers the mineral. You need the right plan.

We solve this with “Three Highs.” High alkalinity. High temperature. High agitation. Research from Minerals Engineering confirms this. High pH helps activate spodumene. It suppresses the quartz. This is key. If you miss this, you lose lithium.

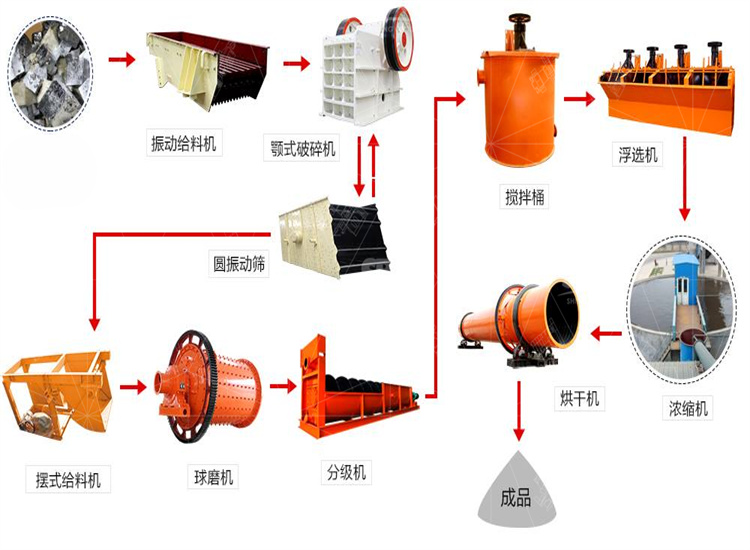

First, we crush the big rocks. We use a Jaw Crusher first. Then a Cone Crusher. We aim for a size below 15mm. This is vital. If rocks are too big, grinding costs go up. If too small, we make slime. Slime is bad for flotation.

Equipment Focus: Hydraulic Cone Crusher

The crusher controls the size. We use a multi-cylinder hydraulic cone. It has a high crushing ratio. The CSS (Closed Side Setting) is adjustable. This controls the output. We set it precise. Why? To save energy later. A standard industry report says crushing uses 50% less energy than grinding. So we crush more. We grind less.

Now we grind the stone. We use a Ball Mill. The target is specific. We need 70% of particles to be -0.074mm (200 mesh). This releases the spodumene. It separates it from waste.

Equipment Focus: Grid Type Ball Mill

Our ball mill is strong. The motor power matches the load. We use steel balls. They hit the ore. The liner protects the shell. We use rubber liners often. They last longer. They are quiet.

Why is hydrocyclone classification critical?

The mill output goes to a cyclone. Heavy stuff goes back. Light stuff goes forward. This loop ensures steady size. If particles are uneven, flotation fails. Big particles sink. Tiny particles float too much. We need the “Goldilocks” size.

This step is often ignored. That is a mistake. Spodumene ore has mud. We call it slime. Slime absorbs chemicals. It wastes money. It covers the spodumene. The collector chemical cannot touch the lithium. So, we wash the ore. We use a Desliming Cyclone. We remove the -0.019mm particles. This improves the grade. It saves reagent cost. Data shows desliming boosts recovery by 10%.

This is the core. We use “Reverse Flotation” or “Direct Flotation.” Usually, direct is better for spodumene. We add NaOH. We add fatty acid. We stir it up.

Equipment Focus: SBM SF Flotation Cell

This machine is special. It sucks its own air. It stirs the pulp. The impeller spins fast. It makes small bubbles. Small bubbles catch minerals better. The tank is deep. This stops the sediment. The stator helps mix. It reduces the swirl. This makes a stable foam layer. Stable foam holds the lithium.

| Parameter | Value Range | Why it Matters |

|---|---|---|

| Pulp Density | 30% – 35% | Ensures proper mixing |

| pH Level | 10 – 12 (Alkaline) | Activates Spodumene surface |

| Temperature | 20°C – 30°C | Helps fatty acid dissolve |

| Agitation Speed | Medium-High | Keeps solids suspended |

Iron is bad for batteries. We must remove it. We use a Magnetic Separator. Usually before flotation. Sometimes after. A High Gradient Magnetic Separator (HGMS) is best. It pulls out weak magnetic iron. This lowers the Fe2O3 content. Battery grade needs Fe2O3 below 0.4%. Our process hits this target.

Let’s look at a real job. A client in Zimbabwe had a problem. Their ore was low grade. Only 1.2% Li2O. They wanted 6.0% concentrate. They used old machines. The recovery was poor. Only 65%. They were losing money.

The SBM Solution

We tested the ore. We found too much slime. We changed the flow.

1. Added a desliming stage.

2. Switched to SBM SF-16 flotation cells.

3. Used a new collector mix (Oxidized Paraffin Soap).

The Result

The grade went up. We hit 6.1% Li2O. The recovery jumped to 87%. The client was happy. They said, “The installation was fast. The team knows their stuff.” This is our OEM power. We design. We build. We install.

| Item | Before SBM | After SBM |

|---|---|---|

| Feed Grade | 1.2% | 1.2% |

| Concentrate Grade | 4.8% | 6.1% |

| Recovery Rate | 65% | 87% |

| Reagent Cost | High | Reduced by 20% |

This is a common pain point. You run the plant. Suddenly, recovery drops. Why? Usually, water quality is the suspect. Flotation hates hard water. Calcium ions hurt the process. They activate the gangue. The waste floats with the lithium.

The Fix: Check your water. Add softeners if needed. Also, check the grind size. If the liner is worn, the grind gets coarse. Coarse rocks don’t float. We suggest checking liners every month. Keep a log. Replace them before they fail.

Chemicals are expensive. Fatty acids cost money. If you use too much, profit dies. Why is usage high? Maybe the temperature is too low. Fatty acids work bad in cold water. They don’t disperse.

The Fix: Warm the pulp. Or use an emulsifier. This spreads the oil. You can use less chemical. We also suggest recycling water. But treat it first. This saves water and chemical.

Size matters. Too big is a waste. Too small is a bottleneck. You need residence time. The ore needs time to attach to bubbles. Usually, 15 to 20 minutes is good.

The Calculation: Calculate your flow rate. Cubic meters per hour. Multiply by required time. This gives total volume. Then divide by cell size. SBM engineers do this for you. We simulate the flow. We pick the right model. We ensure no short-circuiting.

Buying the machine is step one. Installing it is step two. We send engineers to your site. They teach your team. They fix the settings. We provide spare parts. Rubber stators wear out. Impellers wear out. We have stock. We ship fast.

Maintenance is key. Check the belt tension. Check the oil level. Listen to the motor. If it hums loud, stop. Check the bearings. Simple checks save big money. We give you a manual. It lists every check. Follow it.

1. Can you process mica-rich spodumene?

Yes. Mica is tricky. It floats easily. We use a pre-flotation step. We remove mica first. We use acidic pH for this. Then we float lithium. It works well.

2. Do you provide EPC services?

Yes. We do everything. Design. Research. Equipment build. Installation. Training. You give us the mine. We give you the factory. It is turnkey. No headaches for you.

3. What is the lead time for a full plant?

It depends on size. Usually 3 to 5 months. We make machines in our factory. We control the speed. We update you weekly. We know time is money.

Spodumene flotation is science. It is also art. You need good machines. You need good chemistry. Don’t buy cheap fakes. They break. They leak. Trust a real manufacturer.

Choose SBM. We have the labs. We have the data. We have the history. We solve the tough ores. Lithium demand is not stopping. Get your plant running right. Contact us today. Let’s build a profitable mine together.

Whatsapp:+8617329420102

Email: [email protected]

Address: No. 1688, Gaoke East Road, Pudong new district, Shanghai, China.

Online Service : Get Price

We value your feedback! Please complete the form below so that we can tailor our services to your specific needs.