Mining gold is tough work. You need a system that works hard. A 200 tons/hour production line is a serious investment. It is the “Goldilocks” size for many medium mines. Not too big. Not too small. It fits well. This guide explains the tech. We focus on real data. No fluff. We are SBM. We build machines. We know what works.

Many miners ask this. They buy expensive gear. But they lose gold. Why. Usually, the crushing is wrong. The rock is not free. The gold is locked inside. You must break the rock correctly.

The “Liberation Degree” is key. This is a mining term. It means freeing the gold particle. If you dont grind enough, gold stays hidden. If you grind too much, you make “slime.” Slime floats away. You lose money. A 200tph line needs balance.

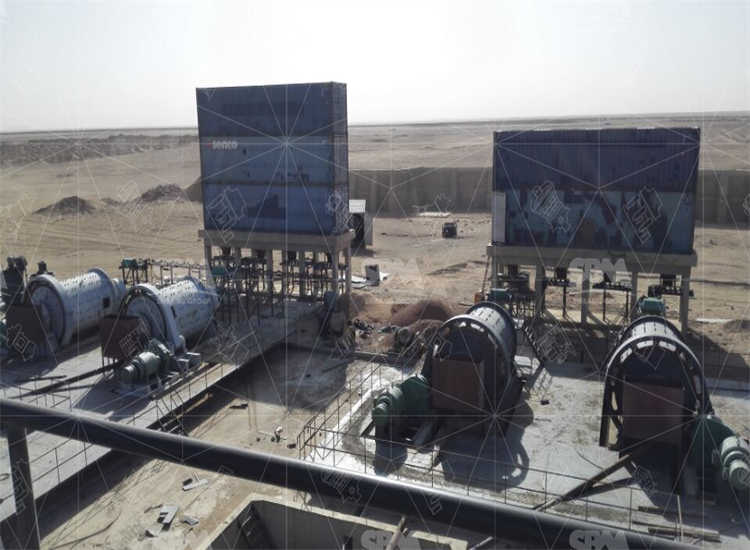

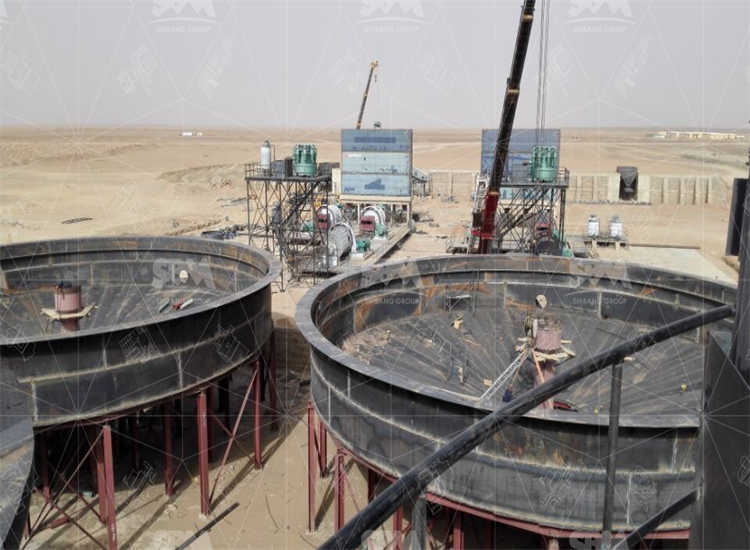

We use specific equipment to fix this. We use a three-stage crush. Then we grind. We control the size strictly. This ensures the chemical or gravity separation works.

The first step is the Jaw Crusher. For 200tph, we often use a PE-750×1060 model. It is a beast. It eats rocks up to 630mm. It spits out 80-140mm rocks.

Think of a giant nutcracker. One plate is still. The other moves. The moving plate swings. It uses an “Eccentric Shaft.” This shaft pushes the plate. The rock breaks under pressure. It falls down. Gravity helps.

Nip Angle: This is the angle between plates. It must be 18-24 degrees. If bigger, rocks pop out. Dangerous. If smaller, less crushing force.

CSS (Closed Side Setting): This is the gap at the bottom. It decides the output size. For 200tph, we set it to 100mm approx. Check this weekly. Wear changes the gap.

This is a big decision. You have hard rock? Or soft rock. For gold, usually hard rock. Granite. Quartz. You need a Cone Crusher.

Impact crushers are for soft stone. Limestone. Coal. Gold ore destroys impact bars. You will change parts every day. Do not do it. Use a Cone Crusher. Specifically, a Symons type or Hydraulic type.

For 200tph, we use a CSB160 or HP300 equivalent. The “Reduction Ratio” is about 4:1. It takes the 100mm rock. It crushes it to 20-30mm. This prepares it for the mill.

This is the heart of the plant. The Ball Mill. It uses steel balls. They tumble inside a drum. They smash the ore into powder.

The drum spins. If too fast, balls stick to the wall. Centrifugal force holds them. They do not drop. No grinding happens. If too slow, they just slide. We aim for 65% to 75% of “Critical Speed.” This makes the balls cascade. They hit the ore hard.

You need big balls and small balls. Big balls break chunks. Small balls grind fine. A mix is best. We suggest a 40% fill rate of the drum volume. Add balls regularly. They wear out.

Mining burns power. Electricity is money. A 200tph line uses lots of kilowatts. How to save?

Look at the motor. Is it matching the load? Many factories sell oversize motors. “Just in case.” This wastes power. We calculate the “Bond Work Index.” This tells us how hard the rock is. We match the motor exactly. No waste.

Also, use Soft Starters. When a big motor starts, it spikes power. The grid hates this. A soft starter eases it in. It saves the belt. It lowers peak demand charges.

Here is the real data. This is what you need for a 200tph setup. We use standard hard rock parameters. Check your ore density. These assume 2.7 t/m3.

| Equipment Name | Model Spec | Power (kW) | Note |

|---|---|---|---|

| Vibrating Feeder | ZSW-490×110 | 22 | Steady feed is crucial |

| Jaw Crusher | PE-750×1060 | 110 | Primary break |

| Cone Crusher | CSB-160 / HP300 | 160 | Secondary break |

| Vibrating Screen | 3YZS-2160 | 30 | 3 decks needed |

| Ball Mill | MQG-2745 | 380 | Heavy load start |

| Spiral Classifier | FG-2400 | 15 (approx) | Or Hydrocyclone |

Let’s talk about a real job. We, SBM, built a line in Zimbabwe. The client had a problem. His old line was 100tph. He wanted 200tph. But his power grid was weak.

The ore was hard granite. Gold was fine-grained. The grid fluctuated. Voltage dropped often.

We skipped the big electric motor on the primary crusher. We used a diesel engine drive for the Jaw Crusher. This saved grid power for the Ball Mill. The Ball Mill needs steady electrics.

We installed a High Pressure Grinding Roll (HPGR) before the mill. It cracks the rock. The mill works less. Energy dropped by 25%.

The client was happy. He hit 180-210 tons per hour. Recovery rate went up 5%. The diesel engine was easy to fix. Local mechanics understood it.

We are the manufacturer. We are not a trading company. This matters. When you buy from a trader, spare parts are a nightmare. They guess the part number. We have the drawings.

SBM offers customization. Maybe your site is hilly. We design the belt conveyors to fit the hill. Maybe you have no water. We add dry stack tailings. We adapt.

You worry about setup. Who will build it? We send engineers. They guide your team. We teach your workers. Installation takes about 30-45 days for this size.

Maintenance Tips:

1. Grease the bearings. Every shift.

2. Check the liners. If worn, change them. Don’t wait.

3. Tighten bolts. Vibrations loosen them.

A lot. Usually, the water-to-solid ratio is 3:1 or 4:1. So for 200 tons of rock, you need 600-800 cubic meters of water. However, you recycle it. Thickener tanks recover 85% of water. Fresh water need is much lower.

Not recommended. Oxide is easy. Cyanide works fast. Sulfide is “refractory.” It needs roasting or bio-leaching. If you mix them, you waste chemicals. Process them separately. We design dual circuits sometimes.

It depends on the rock. For hard quartz, Jaw plates last 2-3 months. Cone liners maybe 2 months. Use high manganese steel. Mn13Cr2 is standard. Mn18Cr2 is better. It costs more but lasts longer.

A 200tph gold line is a system. It is not just machines. It is logic. The Jaw breaks. The Cone refines. The Mill liberates. The Concentrator catches.

Don’t buy the cheapest machine. Buy the heaviest one. Weight means steel. Steel means durability. SBM machines are heavy. We dont cut corners.

Look at your ore report. Is it hard? Get a Cone. Is it sticky? Get a washer. Talk to us. We design the flow for you.

Whatsapp:+8617329420102

Email: [email protected]

Address: No. 1688, Gaoke East Road, Pudong new district, Shanghai, China.

Online Service : Get Price

We value your feedback! Please complete the form below so that we can tailor our services to your specific needs.