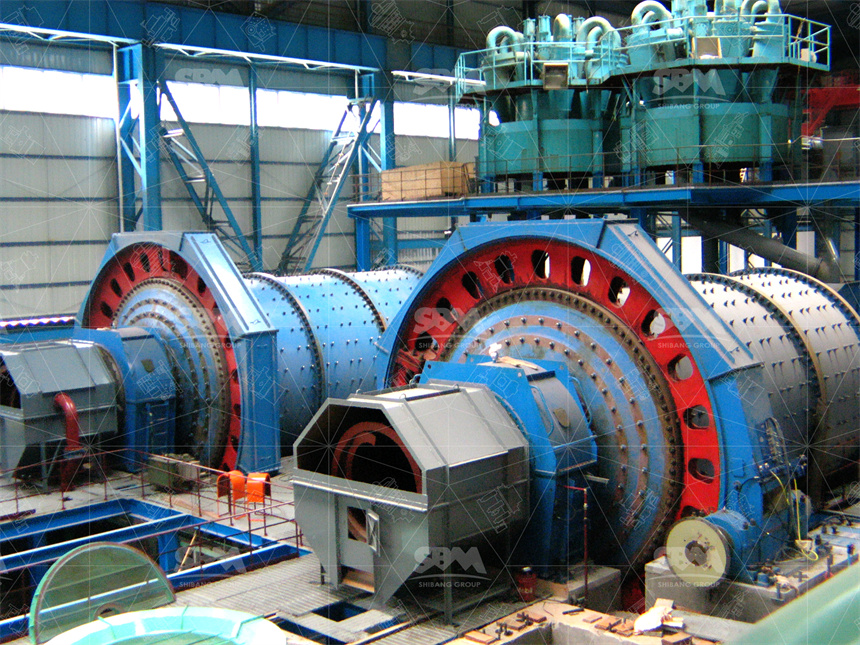

Semi-autogenous grinding (SAG) mills,, has became the central technique in mineral processing sector. When compare to old-fashioned ball mill circuits; SAG mills shows obvious merits in efficiency reduction-ratio maintanence cycle and overall plant economics. Based on field running data and equipment spec, this article explains why SAG solutions are better under today mining circumstance.

SAG mill combine crushing plus grinding. They use both steel-ball and ore itself as breakage media. Feed-size is usually up to 300—400 mm which is far larger than what ball-mills accept. The crushing ratio mostly goes higher than 2900:1 supported with variable-speed drives & powerful motor assemblies (2000~20000 kW). By contrast ball mills handle smaller feeds (below 25mm), and need many stage crushing before grinding. So SAG simplify flowsheet,, cut auxiliary machine load.

SAG mill shell diameter is typically 8–12 m with liners designed for intense impact. Inside, 6%–15% of volum occupied with balls increase ore fracture. Critical speed operation normally kept around 70-75 % to balance attrition+impact. Main specifications are feed-size 300 mm product-size 0.074–0.3 mm and throughput from 220 t/h up to more than 4100 t/h depending ore hardness + configuration. Compared to conventional-ball mills which deliver 20–400 t/h only, SAG shows massive capacity gain.

Records show SAG consume 10–21% less energy per ton processed versus ball circuits that require secondary crush. Motor capacity range 2000–28000 kW, modern drives offer torque-control & load monitoring. Ball-mills usually operate at 90~95% critical load so they need higher media wear. SAG mills media wear is only 0.35–0.7 kg per ton, much below ball mills at 1.2 kg/t. Maintanence-interval go 6–12 month, while ball units need liner-change every 4–6 months, which increase downtime.

In many copper or gold processing-projects SAG mills as primary grinding stage followed by secondary ball mills for finish. Example: in an iron ore plant 5000 t per day,, SAG with 9.5 m diameter & twin 7500 kW motor handle feed 350 mm down to P80 200 μm. Compared to conventional 3-stage crush with ball mill energy-saving was 17% and OPEX down 12%. Plants on high-altitude climates also reported SAG adapt better cause simpler layout, less conveyor, less crusher.

| Factor | SAG Mill | Ball Mill |

|---|---|---|

| Feed dimension | ≤ 350 mm | ≤ 25 mm |

| Reduction-ratio | ~3000:1 | 200:1 |

| Motor capacity | 2000–28000 kW | 200–8000 kW |

| Media wear | 0.35–0.7 kg/t | 1–2 kg/t |

| Maintanence | 6–12 months | 4–6 months |

| Throughput | 220–4100 t/h | 20–400 t/h |

Real-site record shows SAG units with advanced liner material achieved service-life 18 month+, downtime cut 22% vs conventional ball. Operators confirm lower vibration due uniform breakage, this extend bearing service. In South-America copper mine SAG adoption reduced unplanned stop by 30%, daily output surpass plan consistently. Cost benefit analysis indicates annual saving nearly 3 million USD compared to old circuit.

Choosing SAG or ball mill depends on ore-competency, plant scale and CAPEX/OPEX frame. SAG is best for large operation handle competent ores, where less crush stage save investment. Ball mill still useful for small plant or when ore soft and uniform. Guideline: ores with Bond work index higher than 18 kWh/t often favor SAG system. For softer ore below 12 kWh/t ball circuits maybe efficient enough.

SAG outperforms traditional ball mill circuit in most mid- to large-project. It give wider feed-size accept, reduced auxiliary equipment,, lower kWh/t energy and longer maintenance interval. Based on verified operational data conclusion is clear— for modern big ore plants SAG tech deliver undeniable technical+economic superiority. Therefore selection of SAG over ball is not option but necessity for forward looking miners.

Whatsapp:+8617329420102

Email: [email protected]

Address: No. 1688, Gaoke East Road, Pudong new district, Shanghai, China.

Online Service : Get Price

We value your feedback! Please complete the form below so that we can tailor our services to your specific needs.