Iron ore beneficiation is never a simple procedure, it needs a complete flowsheet with several steps of preparation. In my thirty years of trading and plant design experience, I have seen countless operations fail when they ignore staged crushing before ball milling. This practice is not just tradition, it is supported by engineering data, practical running parameters, and long-term maintenance results. Here I will explain why staged crushing is a necessity, not an option, before feeding iron ore into a ball mill.

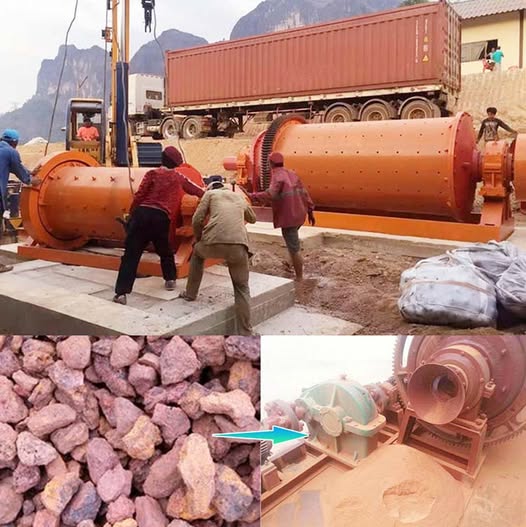

Staged crushing means the ore is reduced through multiple crushers, each with specific chamber geometry and reduction ratio, until it reaches a particle size fit for ball mill grinding. For iron ore, usually a jaw crusher works for primary crushing, a cone crusher or impact crusher does the secondary step, and sometimes tertiary crushers are applied to refine the feed. Without this staged system, ore enters the mill oversized, causing excessive power draw, steel consumption, and unpredictable circulating load.

A jaw crusher operates by compression, the motor power is transferred to an eccentric shaft, and the moving jaw compresses ore against a fixed plate. The crushing ratio normally is 4–6. The CSS adjustment allows precise control of output size. For secondary work, cone crushers run with rotating mantles inside concaves, using eccentric throw and high-speed rotation, often 485–600 rpm depending on model. The motor power ranges from 90 kW to over 250 kW for medium units, well matched with feed capacity of 50–800 t/h. Ball mills, on the other side, require feed below 20 mm for stable grinding; oversized feed will choke the liner profile and increase media breakage. These numbers are not abstract, they are directly measured from running units in iron ore plants.

The reduction ratio must be balanced, not forced. Primary jaw crushers usually handle feed size up to 1200 mm, outputting 100–200 mm. Secondary cone crushers reduce that to 20–50 mm. Finally, the fine crushing stage can reach 10–20 mm, a perfect size for milling. The motor sizing matches these capacities, with power densities designed to maintain energy efficiency. For example, a cone crusher with 160 kW drive easily sustains 200–250 t/h with 35 mm CSS, giving consistent throughput. Such parameters cannot be skipped, otherwise the ball mill will run unstable.

One of the strongest reasons for staged crushing is energy. Milling consumes about 40–50% of total concentrator power. Every millimeter of excess feed size can raise energy demand drastically. By reducing the ore to proper size before milling, you save 10–20% in power draw. Real cases show that circuits with three-stage crushing run with ball mill specific energy as low as 12 kWh/t, while circuits with only one stage reach 16–18 kWh/t. The difference converts into thousands of dollars per day for a medium-scale iron plant. Maintenance cost also lowers, as liners wear slower and grinding balls keep round shape longer.

Crushers demand regular but predictable service. Jaw plates last 3–6 months in iron ore duty, depending on abrasiveness. Cone liners typically last 6–8 weeks in secondary duty. Scheduled maintenance is straightforward, with spare parts available. Ball mills without staged crushing, however, see unexpected shutdowns. Liners break early, discharge screens block, bearings overload. In one plant I visited in India, skipping tertiary crushing increased unplanned downtime by 23%. After adding a fine crusher, the ball mill ran stable for 14 months with only planned relining.

Iron ore often contains high hardness minerals like magnetite and hematite. Their compressive strength exceeds 200 MPa. Direct feeding into a ball mill means severe impact on liners. Crushers are designed for this duty, with proper chamber profile and wear material. A jaw crusher with manganese steel jaw plates, for example, handles magnetite without excessive wear. Cone crushers with chrome-moly liners sustain abrasive hematite with moderate maintenance. The result is a balanced feed for milling, reducing risk of metal contamination and ensuring stable liberation of iron phases.

On a South American project, ore with 600 mm lump size entered a three-stage crushing system: jaw crusher 750×1060, cone crusher PY series, and fine cone crusher for tertiary duty. Output was 15 mm average, 300 t/h. The ball mill then processed at 220 t/h, specific power 13.5 kWh/t. Before staged crushing, the mill consumed 17.8 kWh/t and often overloaded. After staged installation, power dropped 24% and throughput rose 18%. Maintenance cost per ton decreased from 1.9 USD to 1.4 USD. This is not theory, it is field-proven experience.

Staged crushing lines handle not only iron ore but also other ores like copper, gold-bearing rock, or manganese. Jaw crushers adapt to different compressive strengths, cone crushers adjust CSS for variable product, and impact crushers serve for softer gangue. Flexibility allows one plant to process multiple feed types. In Africa, plants running iron ore and later shifting to manganese only needed minor chamber changes, not full plant replacement. This adaptability is critical for long-term projects where ore body composition varies with depth.

When choosing staged crushing equipment, one must balance capacity, feed hardness, required output size, and energy limits. Oversizing equipment only adds cost without benefit. Undersizing leads to bottleneck and mill overfeed. Always design primary crusher feed opening at least 10% larger than maximum lump size. Secondary crusher must handle 60–70% of total throughput with CSS adjusted to mill feed requirement. Motors should match not only installed power but duty cycle, avoiding underloaded conditions. In my experience, plants designed with proper staged crushing see return on investment within 18–24 months, purely from energy and liner savings.

Using staged crushing before ball milling for iron ore is not optional, it is mandatory for sustainable operation. It lowers energy demand, stabilizes ball mill load, extends liner life, and ensures predictable throughput. The parameters I discussed — feed size reduction, CSS adjustment, motor power, energy draw — are real and proven. After decades in the trade, I am confident to state: any iron ore mill without staged crushing is set for premature failure. If you are planning or upgrading a plant, staged crushing must be the first item in design. Ignoring it is a mistake you cannot afford.

Whatsapp:+8617329420102

Email: [email protected]

Address: No. 1688, Gaoke East Road, Pudong new district, Shanghai, China.

Online Service : Get Price

We value your feedback! Please complete the form below so that we can tailor our services to your specific needs.