Gold mining is a serious business. You want to get every piece of gold from the rock. This process is called beneficiation. The most critical part is grinding. It costs the most money. It takes the most energy. Many miners ask us at SBM. Which machine is better? Is it the Ball Mill? Or is it the Rod Mill? The answer is not simple. It depends on your gold. It depends on your process. This article will help you decide.

We will look at the facts. We will look at the data. We use simple words so everyone understands. SBM has 30 years of experience. We know what works. We know what fails. Let us start the comparison.

You must understand the working principle. This is the base of your choice.

Rod mills use long steel rods inside. The cylinder spins. The rods tumble. The key term is “Line Contact”. The rods touch the ore along a line. This is important. Why? Because it breaks big rocks first. It protects small particles. It does not grind too fine. We call this “selective grinding”. It creates less dust. It creates less slime. This is good for gravity separation.

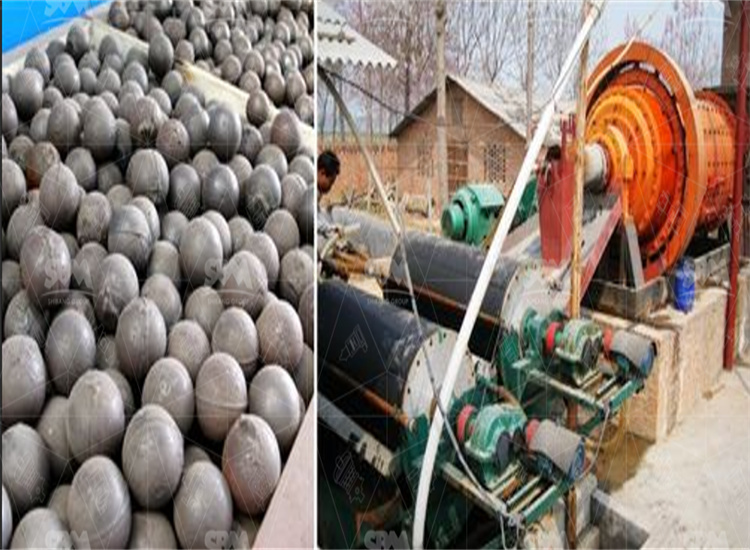

Ball mills use steel balls. The cylinder spins. The balls drop. The key term is “Point Contact”. The ball hits the rock at one point. The impact is strong. It is random. It grinds everything. It makes very fine powder. This is good for flotation. It is good for cyanidation. It exposes the gold fully. But it can make slime.

Data speaks the truth. We compare the technical specs here. This helps you calculate costs. It helps you plan the plant.

| Feature | Rod Mill (SBM MBR Series) | Ball Mill (SBM MQ Series) |

|---|---|---|

| Grinding Media | Steel Rods (50-100mm dia) | Steel Balls (20-120mm dia) |

| Contact Type | Line Contact | Point Contact |

| Feed Size | Up to 50mm | Usually 20mm or less |

| Output Size | 0.5mm to 3mm (Coarse) | 0.074mm to 0.4mm (Fine) |

| Capacity Stability | Stable output | High capacity |

| Over-grinding | Very Low | High risk |

This is a painful question. You buy expensive equipment. But the gold is lost. Why happen? Often , it is the wrong mill choice. Let us analyze this.

Gold is heavy. Rock is light. If you grind rock to powder , it becomes “slime”. Slime is like mud. It covers the gold. The chemicals cannot touch the gold. The gravity machines cannot catch the gold. Rod mills prevent this. They stop grinding when rock is small enough. This protects the gold particles. SBM tests show this often. Rod mills improve gravity recovery by 15%.

Hard rock needs impact. Ball mills give high impact. If rock is very hard (Bond Index > 16) , rod mills might struggle. They might bend rods. Ball mills are tough. They handle hard quartz gold ore well. You must check ore hardness first.

Theory is good. But practice is better. Here are two real stories from SBM clients. They show how to choose.

Location: Bulawayo , Zimbabwe

Ore Type: Quartz vein gold. Visible gold.

The Problem: The client used a ball mill before. The gold was very fine. The shaker table lost 40% of gold. He was losing money every day.

SBM Solution: We changed the design. We installed an SBM Rod Mill (Model MBR2130). We set the CSS to produce 1mm particles.

Why: The rod mill reduced slime. It kept gold particles big. Gravity tables catch big gold easily.

Result: Recovery rate went up to 85%. The client said , “SBM saved my mine. The machine runs smooth. No more lost gold dust.”

Location: Northern Sudan

Ore Type: Sulfide gold ore. Gold is inside the sulfide.

The Problem: The gold was “locked”. It needed fine grinding. 200 mesh (0.074mm). The old mill was too coarse.

SBM Solution: We installed an SBM Ball Mill (MQG 2736). We used high chrome steel balls.

Why: We needed point contact. We needed to break the sulfide crystal. This exposes the gold to cyanide.

Result: Leaching efficiency hit 96%. The power consumption was low. The grid drive motor is strong.

You are an engineer? Or a boss? You need to know these numbers. They define the machine quality.

This is how full the mill is. Too full is bad. Too empty is bad. SBM mills are optimized for 40%. Why? It gives best impact force. It saves electricity.

The mill spins. If too fast , balls stick to wall. If too slow , they slide. You need them to drop. We call this “cascading”. SBM motors set this speed perfectly. It ensures grinding action.

Rod mills are long. Length is 1.5x or 2x of diameter. Why? Rods need space to stay straight. Ball mills are shorter. L is often equal to D. This is standard design.

Buying is step one. Running is step two. SBM machines are easy to fix. We care about your downtime.

Installation Tips:

Maintenance Cycle:

SBM liners are Mn13 steel. They last long. Usually 6-12 months. This reduces your cost. You do not stop production often.

You probably have these questions too. We answer them now.

Answer: You can , but it is not good. Why? Because balls create fines. If you want 1mm or 2mm output , balls will make too much dust. This wastes energy. Use a Rod Mill for coarse work. It is more efficient.

Answer: Usually the Ball Mill uses more. Why? Because it spins heavy balls. It often runs longer to get fine powder. Rod mills use less power per ton. But , ball mills do more work (finer reduction). Efficiency depends on the target size.

Answer: No. Do not do this. Why? The end caps are different. The liners are different. Rod mills have special liners to keep rods straight. Balls will break these liners. SBM does not recommend this. It voids warranty.

So , which one? Here is a simple decision tree for you.

You use Gravity Separation (Jig , Shaker Table , Centrifuge). You want output size 1mm – 3mm. You want less slime. You have brittle ore.

You use Flotation or CIL/CIP. You need very fine powder (0.074mm). Your ore is very hard. You want high capacity continuous run.

SBM makes both. We export to 120 countries. We help you test the ore. We design the flow. Do not guess. Ask the expert. Your gold mine deserves the best tools.

Contact SBM today. Let us build your plant. Efficient grinding is profit.

Whatsapp:+8617329420102

Email: [email protected]

Address: No. 1688, Gaoke East Road, Pudong new district, Shanghai, China.

Online Service : Get Price

We value your feedback! Please complete the form below so that we can tailor our services to your specific needs.