Estimating maintenance costs for cone crushers is vital for mine profits. This guide helps you calculate expenses using real data and field logic. We focus on parts wear, power use, and service intervals to keep your plant running.

A cone crusher breaks rocks between a fixed bowl and a moving mantle. The mantle moves in a circle inside the machine. This action squeezes the ore until it breaks. Engineers call the smallest opening the Closed Side Setting (CSS). The largest opening is the Open Side Setting (OSS). These settings control your final product size. The reduction ratio measures how much the rock shrinks. For example, a 4:1 ratio means a 100mm rock becomes 25mm. High-speed rotation helps create more crushed material per hour. Correct motor power matching prevents the machine from stalling during heavy loads.

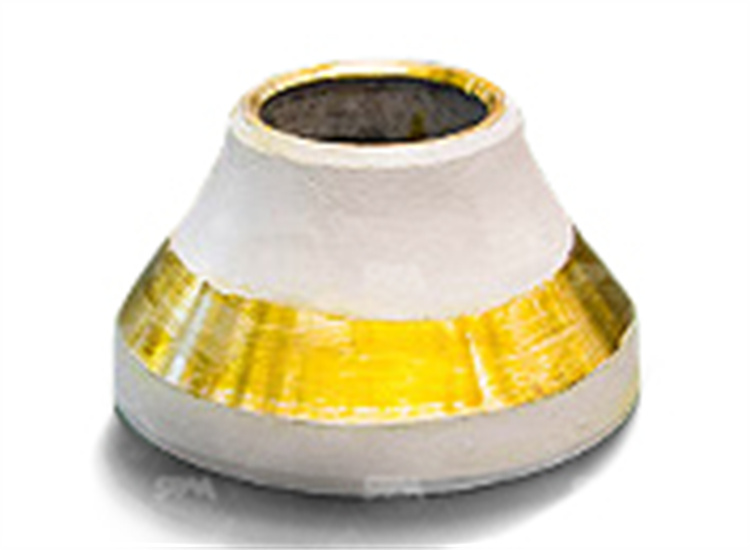

Liners are the most expensive part of daily maintenance. The mantle and bowl liner take the most abuse. Hard rocks like granite wear metal down fast. Experts use the Bond Abrasion Index (Ai) to predict wear life. According to the Journal of Mining Science, a 0.5 Ai score means parts last 400 hours. If your rock is softer, parts may last 800 hours. You must check the thickness of liners every week. Replacing them too late ruins the crusher frame. Replacing them too early wastes good metal. We suggest measuring the CSS daily to track wear rates accurately.

Cone crushers need clean oil to protect internal bushings. The lubrication system cools the machine and removes dust. You should change the oil every 2,000 operating hours. Dirty oil causes heat to build up in the eccentric bushings. High heat leads to sudden bearing failure. A standard medium crusher needs about 400 liters of specialized gear oil. You also need to replace the oil filter every 500 hours. Regular oil analysis costs little but saves the motor. Clean oil reduces friction which lowers your total power bill. It ensures the machine stays within its design temperature range.

Electricity is a hidden maintenance cost for many mines. A motor that works too hard wears out internal seals. Most cone crushers run at 75% to 85% of their rated power. Running at 100% capacity all day increases the heat stress. This stress makes the gaskets brittle and causes leaks. Use a power meter to track energy spikes during the day. Spikes often mean the feed size is too large for the chamber. Proper feed grading allows the crusher to draw steady current. This stability extends the life of the electric motor and drive belts.

Routine checks prevent small cracks from becoming massive breaks. We recommend a daily 15-minute walk-around before the shift starts. Look for loose bolts on the mainframe and adjustment ring. Check the hydraulic pressure for the tramp release system. This system protects the crusher if a piece of steel enters. Minerals Engineering reports that 30% of failures come from poor bolt tension. Every 250 hours, you should inspect the drive belt tension. Loose belts slip and waste energy. Tight belts put too much pressure on the motor bearings.

| Machine Model | Feed Size (mm) | CSS Range (mm) | Liner Life (Hours) | Power (kW) |

|---|---|---|---|---|

| SBM HP200 | 185 | 10-30 | 450-600 | 132 |

| SBM HP300 | 230 | 13-38 | 500-750 | 220 |

| SBM HP500 | 335 | 19-51 | 600-900 | 315 |

Labor costs depend on the ease of access to parts. Modern SBM designs allow top-access for liner changes. This feature reduces the time needed for a rebuild. A traditional crusher might take 24 hours to re-line. Our design cuts that time down to 12 hours. Shorter downtime means more production for your site. You need at least two skilled technicians for a safe change-out. Specialized tools like hydraulic wrenches speed up the process. Training your staff on SBM manuals reduces human errors. Well-trained teams find leaks before they stop the whole plant.

A copper mine in Chile used two SBM HP300 units. The ore was very hard with high silica content. Initially, they changed liners every 350 hours. We analyzed their feed curve and found too many fines. Fines cause “pancaking” in the crushing chamber. We adjusted the pre-screen to remove material under 15mm. This change increased liner life to 520 hours. It also reduced power draw by 12%. The customer said the SBM units were very stable. They liked how the hydraulic system handled uncrushable iron. Maintenance costs dropped by 18% in the first year.

An aggregate plant needed 20mm road stone in a wet climate. They installed a SBM secondary cone crusher. The wet feed often caused clumping in older machines. Our team suggested a high-speed eccentric setting. This setting gave the material more “flips” in the chamber. It prevented clogging and kept the throughput at 250 tons per hour. The client noted that the SBM seals kept water out of the oil. They saved $5,000 USD per year on oil changes alone. The ease of maintenance helped them meet tight delivery deadlines.

To find your cost, add parts, labor, oil, and power. Divide this total by the tons produced in a month. For example, spend $10,000 on a machine that makes 100,000 tons. Your maintenance cost is $0.10 per ton. Most efficient mines target a cost below $0.15 per ton. If your cost is higher, check your feed size. Large rocks cause “bell-mouthing” on the liners. This wears out the top of the liners too fast. Balanced feeding ensures the entire liner surface does work. This spreads the wear and lowers the cost per ton.

Sensors can track heat and vibration in real-time. SBM crushers can include vibration sensors on the frame. High vibration means the foundation is loose or the shaft is bent. Catching this early prevents a catastrophic shaft break. A broken shaft can cost $50,000 to replace. A sensor costs much less and warns you in seconds. We also monitor the return oil temperature. If the temperature rises fast, a bushing is failing. You can stop the machine and fix it before it melts. Digital tools turn “fix it when it breaks” into “fix it before it breaks.”

Question: How do I know if my liners are worn out?

Answer: Check your CSS adjustment daily. If the adjustment ring is at its lowest point, the liners are thin. You will also see a drop in hourly production. The rocks coming out will look flaky or too large. Measure the liner thickness during stops. If the metal is less than 25mm thick, change it. Why? Because thin liners can crack and damage the bowl or mantle seatings.

Question: Why is my crusher vibrating too much?

Answer: Excessive vibration usually comes from three things. First, the feed might have “tramp iron” or uncrushable metal. Second, the feed might be unevenly distributed in the chamber. Third, the mounting pads might be worn out. Why does this matter? Vibration kills bearings and cracks the main frame over time. Always use a feed distributor to fill the chamber 360 degrees around the mantle.

Question: What is the best way to store spare parts?

Answer: Keep liners in a dry place to prevent heavy rust. Rust makes it hard to seat the liners properly. Store seals and O-rings in a cool, dark box. Heat and sunlight make rubber brittle. Why? Brittle seals leak oil immediately after installation. Always keep one full set of liners and one set of filters on site. This prevents waiting weeks for a shipping container during a breakdown.

Choose a crusher based on your hardest rock, not the average. Ensure the motor has enough torque for cold starts. Check that the manufacturer provides local technical support. SBM offers on-site training for all new installations. We help your team understand the hydraulic control system. A well-selected machine runs at 80% capacity for best longevity. Avoid over-sizing the crusher as it leads to poor product shape. A matched system lowers your long-term maintenance bill. Always look for a robust frame design that handles high crushing forces.

Maintenance cost is not just about the price of steel. It is about the life of the machine and the speed of service. Using SBM equipment ensures you get high-quality parts and expert advice. Focus on oil cleanliness and proper feed sizing. Track your wear rates every week to avoid surprises. A proactive plan saves money and keeps your mine profitable. Start by measuring your current cost per ton today. Then, use our tips to bring that number down through better operation. Reliable crushing starts with disciplined maintenance habits.

Whatsapp:+8617329420102

Email: [email protected]

Address: No. 1688, Gaoke East Road, Pudong new district, Shanghai, China.

Online Service : Get Price

We value your feedback! Please complete the form below so that we can tailor our services to your specific needs.