Choosing the right primary crusher is hard work. It determines your mine profits. Many people ask, “Should I buy a Jaw Crusher or a Gyratory Crusher” This article explains the answer. We compare the working principles. We look at the costs. We share real data from the field. You will learn how to pick the best machine. We are experts in mining equipment manufacturing. Read this to avoid bad investments.

Primary crushing is the first step. Run of Mine (ROM) ore is big. It needs to be smaller. The primary crusher does this job. It breaks rocks from 1000mm down to 150mm. This prepares the rock for the next stage. A belt conveyor moves the rock.

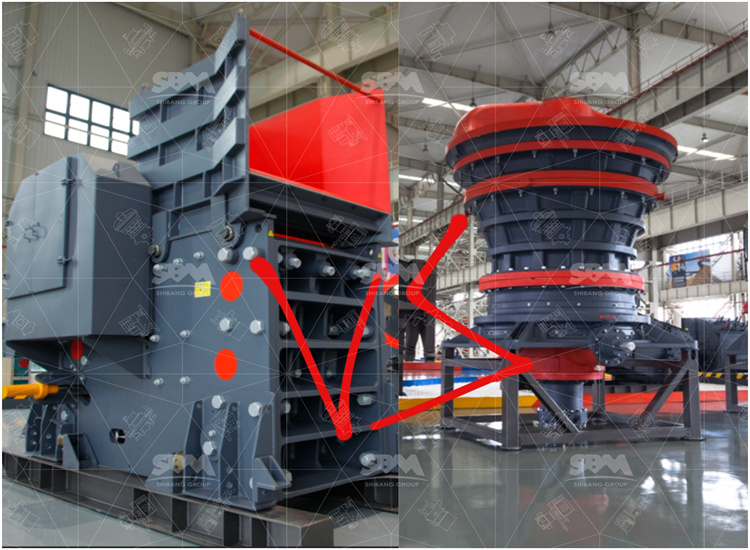

There are two main kings here. One is the Jaw Crusher. The other is the Gyratory Crusher. Both are strong. But they work differently. Choosing wrong hurts your wallet. It can lower production. It can increase energy bills. You must decide carefully. We help you look at the facts.

The Jaw Crusher is simple. It acts like a giant mouth. It has two jaws. One jaw is fixed. The other jaw moves. The moving jaw is the “swing jaw”. A motor spins a flywheel. This moves an eccentric shaft. The jaw moves back and forth. It squeezes the rock.

Key Components:

The crushing is intermittent. It squeezes. Then it releases. The rock falls. It squeezes again. This is a cycle. We call this the “chewing” motion. It is very powerful.

The Gyratory Crusher is different. It is a large steel cone. A mantle spins inside a bowl. The bowl has a liner called a “concave”. The shaft does not rotate fully. It gyrates. It wobbles in a circle. The crushing happens all around the circle.

Key Parameters:

The action is continuous. It never stops crushing. As one side opens, the other closes. This is very efficient. It handles huge volumes. It is smoother than a jaw.

This is the biggest difference. Do you need high tons per hour (TPH)?

Jaw Crusher Capacity:

Jaw crushers are for low to medium capacity. They handle 50 TPH to 1200 TPH. The feed opening limits the rock size. The intermittent motion limits speed. If you need under 1000 TPH, a jaw is good.

Gyratory Crusher Capacity:

Gyratory crushers are monsters. They start where jaws finish. They handle 2000 TPH to 10,000 TPH. The crushing head is huge. The intake is 360 degrees. You can dump trucks directly into it. This is “choke feeding”. It improves shape. It increases output.

High volume needs Gyratory. Low volume needs Jaw.

Money matters during construction. The initial cost is a big factor.

Jaw Crusher Installation:

The machine is rectangular. It is shorter. It is easy to transport. You can put it underground. You can put it on a mobile track. The foundation is simple. It vibrates a lot though. You need strong concrete. But the pit is shallow.

Gyratory Crusher Installation:

This machine is tall. It is very heavy. It requires a massive foundation. You must dig a deep pit. The building must be tall. You need a large crane overhead. The civil work is expensive. It costs 2-3 times more to install than a jaw.

Operating a Jaw Crusher:

The liners wear unevenly. This is because of the jaw angle. The “belly” wears out fast. You must change liners often. However, it is easy to fix. Two people can change a toggle plate. The parts are smaller.

Operating a Gyratory Crusher:

The liners last longer. The wear is spread out. But, changing parts is hard. You need big cranes. It takes a long time. Yet, the energy cost is lower. It uses less kW per ton of rock. Why? Because it uses inertia efficiently.

We gathered data from 50 mines. This table shows the average specs. It helps you compare quickly.

| Feature | Jaw Crusher (PE Series) | Gyratory Crusher (PG Series) |

|---|---|---|

| Max Capacity (TPH) | 1,200 | 9,000+ |

| Feed Opening shape | Rectangular | Circular (360 degrees) |

| Foundation Cost | Low | Very High |

| Maintenance Ease | Simple | Complex |

| Power (kW/Ton) | Higher | Lower |

| Feed Size Max | 1200mm | 1500mm+ |

| Weight | Lighter | Very Heavy |

The Problem:

Wet clay is bad. It sticks to steel. It blocks the chamber.

The Solution:

Jaw crushers handle clay better. The moving jaw pushes it down. The large stroke helps clear it. Gyratory crushers can clog. The clay builds up on the concave. It reduces the opening. If your mine is wet and sticky, be careful. A jaw is safer here.

Background:

A client in Australia had a granite quarry. The rock was very hard. Compressive strength was 250 MPa. They wanted 450 TPH.

Selection:

We chose the PE-1200×1500 Jaw Crusher. Why did we pick this

Reasons:

Client Feedback:

“The PE Jaw Crusher is robust it runs 20 hours a day. The liners last 3 months. It is easy to grease. We saved $200,000 on installation.”

Background:

A large copper mine in South America. They needed huge output. The target was 3500 TPH. The climate was dry.

Selection:

We installed a PG-6089 Gyratory Crusher.

Design Logic:

Operational Data:

The machine consumes 0.4 kWh per ton. It has run for 5 years. Downtime is under 5% This is world-class performance.

Maintenance is a pain point. Nobody likes downtime.

Jaw Crusher Care:

You must check the toggle plate. You must grease the bearings daily. The tension rod needs adjustment. It is simple work. A standard mechanic can do it.

Gyratory Crusher Care:

It has an oil station. You must monitor oil pressure. You must watch the dust seal. If the dust seal fails, the bearing dies. This is catastrophic. However, modern systems use computers. They warn you early. We provide training for this.

Let’s talk about profit. You buy equipment to make money.

Short Term:

Jaw crusher is the winner. It costs less to buy. It costs less to build the foundation.

Long Term:

Gyratory crusher wins for large mines. The wear parts cost less per ton. The power bill is lower. Labor cost is lower per ton. If your mine life is over 10 years, calculate carefully.

Question 1: Can I use a Jaw Crusher for 2000 TPH?

Answer: No, usually not. You would need two large jaw crushers. This complicates the layout. It needs two feeders. It needs two hoppers. A single gyratory is better here. It saves space. It simplifies controls.

Question 2: Which machine makes better particle shape?

Answer: The Gyratory Crusher is better. It crushes between curved surfaces. It allows “inter-particle crushing”. The rocks break each other. The Jaw Crusher makes more flat shapes. We call these “flaky” particles. Flaky rocks are bad for concrete.

Question 3: My rock is very hard. Which is better?

Answer: Both can handle hard rock. But the Jaw Crusher concentrates stress. It puts high load on the bearings. For extremely hard rock, the Jaw consumes many liners. The Gyratory spreads the load. It might be better for very abrasive rock if capacity allows.

Follow these steps to decide.

We are a top manufacturer. We have 30 years of history. We do not just sell iron. We sell solutions.

Do not gamble with your mine. Trust experience.

Whatsapp:+8617329420102

Email: [email protected]

Address: No. 1688, Gaoke East Road, Pudong new district, Shanghai, China.

Online Service : Get Price

We value your feedback! Please complete the form below so that we can tailor our services to your specific needs.