You work in mining. You break rocks.. Choosing equipment is hard. We know this struggles. We make crushers for years. Two types confuse people often. The Spring Cone Crusher. And the Multi-cylinder Hydraulic Cone Crusher. Which one is best?? It depends on your site. This guide explains everything.

First we look at how they work. It is physics.. The goal is breaking stone.

The Spring Cone Crusher (The Old Classic)

This machine is traditional. It has been around for decades.. It uses a mantle and concave. The mantle spins. It wobbles inside the concave. Rock falls in the gap. The gap gets small. The rock breaks.

Why use springs?? Safety. Sometimes iron gets in. Springs let the top lift up. The iron passes through. The machine does not break. This is overload protection. But springs are old tech.

The Multi-cylinder Hydraulic Cone Crusher (The Modern Power)

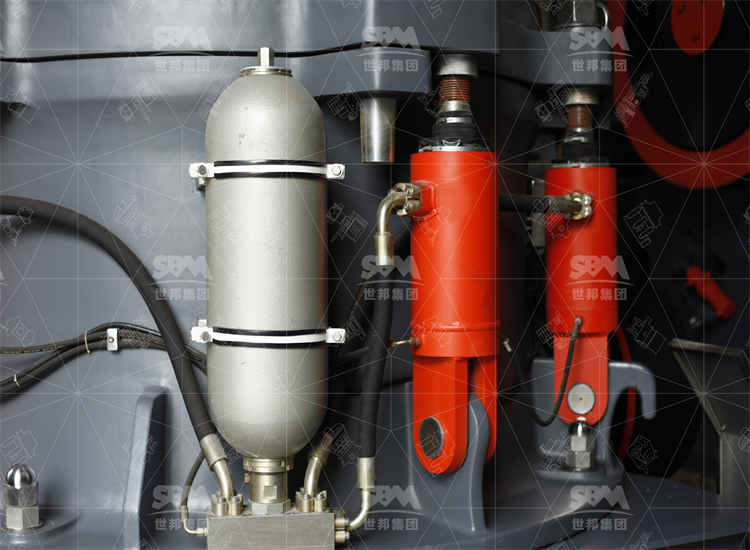

This is the upgrade.. It works similar. But no springs. It uses hydraulic cylinders. Oil pressure holds the frame. If iron enters.. hydraulic pressure releases. It is faster. It is safer.

Key Terms You Must Know

We explain technical words here.. Simple for you.

This section is important. Read carefully..

The Multi-cylinder is faster. Much faster. The main shaft spins high speed.. Why this helps? It creates “Lamination Crushing”.

What is Lamination Crushing?

Think of a sandwich.. Rocks hit rocks. Not just metal hitting rock. The stones break each other. This happens at high speed. The result is cubes. Good shape for concrete.. The Spring Cone is slower. It squeezes rock. It makes some needles. It makes flakes.. Bad for high roads.

Data from Industry Tests

We check journals. Mining Engineering magazine data shows this. High speed improves shape 15%.. Multi-cylinder has higher density. Capacity goes up 30% compared to spring cone. This is fact..

We compare them side by side. Look at the data..

| Feature | Spring Cone Crusher (PY Series) | Multi-cylinder Hydraulic (HP Series) |

|---|---|---|

| Drive Speed | Low (300-400 RPM) | High (700-1000 RPM) |

| Protection | Mechanical Springs | Hydraulic Accumulators |

| Adjustment | Manual / Slow Hydraulic | Automatic Button Press |

| Product Shape | Fair (Some flakes) | Excellent (Cubic) |

| Automation | Low Level | High Level (PLC) |

| Price | Cheaper | Higher Investment |

Why the difference?? The hydraulic motor is stronger. It pushes harder.. The crushing force is bigger. Hard rocks break easier.

This is a big pain point. You hate downtime. We hate it too..

Problem: The Machine Jams

It happens. Power goes out.. The crusher is full of rock. We call this a “stalled machine”.

Spring Crusher Solution:

It is hard work. You might need jacks. You might need to clear rocks manually.. It takes hours. Dangerous work too. Workers get tired.

Multi-cylinder Solution:

Push a button. The hydraulics lift the top. The cavity opens.. Rocks fall out. Lower the top. Start again. It takes 10 minutes. Why choose stress?? Choose hydraulics.

Wear Parts Replacement

The mantle and concave wear out. Changing them is heavy.. Hydraulic cone designs are smarter. Parts come out easier. No epoxy glue needed in some new models. Save time.

We share real site data. Proof of our work..

The Result: The customer had low money. Spring cones are cheap to buy.. They work fine. But shape was okay, not great. Maintenance takes long. But it paid off in 6 months.. Good for starters.

The Result: Basalt is tough. It eats steel.. The Multi-cylinder crushing force broke it well. The shape was cubic. Selling price was 20% higher.. The PLC system monitored heat. No failures in 12 months. Customer is very happy..

Don’t guess. Follow this logic.. Use this rule.

Why follow this?? Because wrong machine costs money. Wrong machine stops production.

Electricity is money.. You pay bills every month.

Many think bigger motors use more power. This is wrong thinking.. Efficiency matters. The Multi-cylinder has a big motor. But it produces more tons per hour.

Calculation Example:

Result: Hydraulic is cheaper to run. It uses power better.. The crushing ratio is higher. You recirculate less rock. Less belt wear too.

Some old bosses fear computers.. “It is too complex,” they say.

Installation:

Spring cone needs big foundation. It vibrates a lot.. Hydraulic cone is compact. Integrated base frame. Install is fast. 3 days vs 7 days.

Operation:

Hydraulic has a screen. It shows oil temp. It shows pressure.. It warns you. Spring cone tells you nothing. You listen to sound.. Only old experts can run Spring cones well. New kids can run Hydraulic cones.

Why is my concave wearing unevenly??

Reason: Bad feeding.. You are not filling the chamber. Solution: Keep it full. We call this “choke feeding”. Hydraulic cones like this. It wears even.

Why does the main shaft break??

Reason: Too much iron. Or fatigue.. Solution: Hydraulic protection is instant. Springs are slow. The oil reacts in milliseconds.. Shaft is safe.

Q1: Can I convert my Spring Cone to Hydraulic?

No. The frame is different.. The internal oil paths are complex. You must buy new. It is a different beast.

Q2: Is hydraulic oil expensive to maintain?

Not really.. You change filters. Keep dust out. If seals are good, oil lasts long. It is cheaper than replacing broken springs.

Q3: Which one makes more dust?

Both make dust.. It is crushing. But Hydraulic makes more “fines” (sand). If you want sand, it is good. If not, adjust the CSS..

Mining is tough business.. You need reliability.

The Spring Cone is a warrior. It is old. It is cheap. It works for soft rock. It works for simple plants.. If you have small money, buy it. It will work.

The Multi-cylinder Hydraulic is the master. It is precise.. It makes better product. It runs cheaper. It fixes jams fast. If you have the budget, buy it. It pays back fast.

Look at your rock.. Look at your bank. Call us if unsure. We help you choose right.

Whatsapp:+8617329420102

Email: [email protected]

Address: No. 1688, Gaoke East Road, Pudong new district, Shanghai, China.

Online Service : Get Price

We value your feedback! Please complete the form below so that we can tailor our services to your specific needs.