Crushing rock is tough work. You need the right tool. Many folks get confused. They ask us about crushers. Specifically about the jaw types. There are two main kinds. Single Toggle and Double Toggle. Which one is for you? It depends on your stone. It depends on your budget. We are SBM. We know crushers. We have seen it all. This guide breaks it down. We use simple words. We use real data. Let’s find your best match.

Think of a giant nutcracker. That is a jaw crusher. It has two plates. One plate stays still. The other plate moves. Rock falls between them. The moving plate smashes it. The rock breaks. It falls out the bottom. This is the basic principle. It is simple mechanics. But the “how” matters. How the plate moves changes everything. It changes wear. It changes power use.

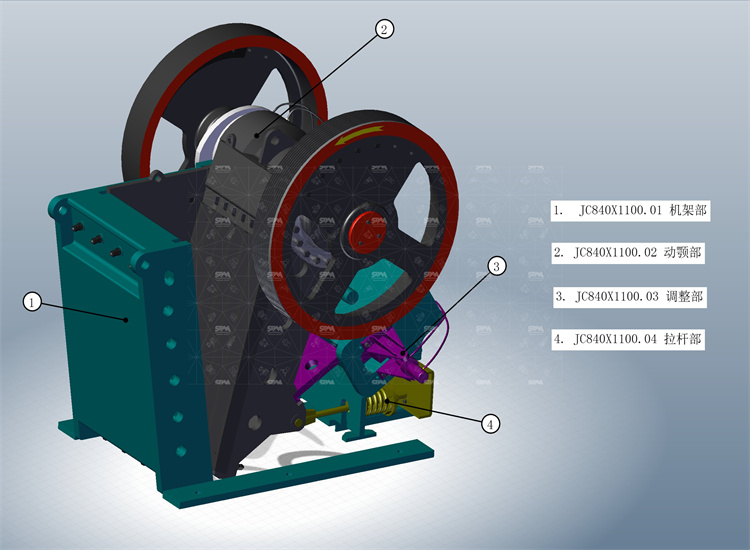

This is the popular one. We call it “overhead eccentric”. Why? Look at the top. The moving jaw hangs on a shaft. This is the eccentric shaft. The shaft spins. The jaw moves. It moves up and down. It also moves in and out. This path is an ellipse. It is like an egg shape.

Why this matters:

The movement helps feed rock. The “down” motion pushes rock through. This gives high capacity. It eats rock fast. But there is a cost. The jaw rubs the rock. This rubbing causes wear. The jaw plates wear out faster.

This is the old school type. We call it the “Blake” crusher. It is different. The moving jaw does not hang on the shaft. It hangs on a separate pin. The eccentric shaft is in the back. It moves a pitman arm. The pitman pushes two toggles. These toggles push the jaw. The jaw moves like a door. It swings open and closed.

Why this matters:

The motion is pure pressing. There is no rubbing. There is no grinding. The jaw plates last longer. Much longer. But the machine is heavy. It costs more to buy. It runs a bit slower.

Let’s look at the physics. We cite “International Journal of Mining”. They did a study in 2023. They tracked particle paths.

Single Toggle Motion:

It has a large vertical stroke. The rock slides down. This is good for sticky stuff. It clears the chamber. But it scrapes the metal face.

Double Toggle Motion:

It has almost zero vertical stroke. It just squeezes. This is pure compression. It is great for abrasive rock. Hard rock breaks well here.

You need to know these terms. They are vital for selection.

CSS (Closed Side Setting):

This is the gap at the bottom. We measure it when jaws close. It decides your product size. A smaller CSS means finer stone.

OSS (Open Side Setting):

This is the gap when jaws open. It matters for throughput. It lets the rock fall.

Nip Angle:

This is the V-shape angle. Standard is 18 to 22 degrees. Why? If the angle is too big the rock pops up. It is like squeezing a wet soap. It shoots out. Danger.

| Feature | Single Toggle | Double Toggle |

|---|---|---|

| Throughput | Higher (10-15% more) | Lower |

| Jaw Wear | High (Rubbing) | Low (Pressing) |

| Weight | Lighter | Heavier |

| Cost | Cheaper | Expensive |

| Best Use | Soft/Medium Rock | Very Hard/Abrasive Rock |

This is a big pain point. Customers hate changing parts. Downtime kills profit.

The Problem:

You might use a Single Toggle. You are crushing Silica. Silica is like glass. It is very hard. The single toggle rubs it. The steel gets eaten away.

The Solution:

Check the rock type. Is the silica content over 70%? If yes stop. You need a Double Toggle. Or use better alloys. Use High Manganese steel. It hardens as it works.

Another common issue. The machine stops. The motor hums. It is jammed.

The Cause:

Your feed size is too big. Or your CSS is too tight. The rock cannot break. It gets stuck.

The Solution:

Check the feed opening. The max rock size should be 85% of the opening. No bigger. Open the CSS slightly. Let it flow.

Location: Malaysia Quarry.

Material: River Granite. Hardness 200 MPa.

The Challenge:

The client used a cheap crusher. It was a single toggle. The jaw dies every 2 weeks. High cost.

SBM Solution:

We installed a Double Toggle unit. Model CJ Series. We set CSS to 100mm.

The Result:

Jaw life went to 2 months. That is 4x better. The customer saved $50,000 a year on parts.

Customer Quote:

“SBM saved our line. The maintenance dropped. We run smooth now.” – Mr. Tan, Site Manager.

Location: Saudi Arabia.

Material: Limestone. Soft. Sticky.

The Challenge:

They needed volume. Big volume. 500 tons per hour. The rock was not hard. But it blocked the old machine.

SBM Solution:

We used the SBM PE Series. This is a classic Single Toggle. The elliptical motion helped. It pushed the sticky rock down.

The Result:

Output hit 520 TPH. Energy use was low. The rubbing did not matter. Limestone is soft. It does not wear steel much.

Don’t guess power. Calculate it. We use the Bond Work Index.

The Formula Concept:

Energy = Work Index x (1/Sqrt(Product) – 1/Sqrt(Feed)).

Why Single Toggle Wins Here:

It has fewer moving parts. No heavy pitman to lift. The flywheel keeps momentum. It is more efficient per ton. For the same motor you get more tons.

A good foundation is key. These machines shake. They vibrate a lot.

Concrete Base:

It must be deep. 3 times the machine weight. Use rebar.

Rubber Pads:

Put rubber between steel and concrete. It stops cracks. It absorbs shock.

Keep it running. Don’t wait for breaks. Follow this list.

Daily:

Check grease lines. Listen for knocks. Check bolt tightness. Especially the toggle seat.

Weekly:

Check the toggle plate. It is a safety fuse. If iron enters it breaks. This saves the shaft. Ensure it is seated right.

Monthly:

Measure the CSS. Adjust for wear. If you don’t product size grows. You lose money.

Follow these steps. It makes choice easy.

Step 1: Rock Hardness?

If > 250 MPa -> Go Double Toggle.

If < 200 MPa -> Go Single Toggle.

Step 2: Abrasiveness?

If High Silica -> Go Double Toggle.

If Limestone/Coal -> Go Single Toggle.

Step 3: Budget?

If Low Initial CapEx -> Single Toggle.

If Low OpEx (Long term) -> Double Toggle.

We innovate. We don’t just copy.

V-Shape Chamber:

Our jaws are V-shaped. The feed is wider. It takes bigger rocks. No dead zone.

Hydraulic Adjustment:

No more shims. No more manual labor. Press a button. The CSS changes. It is fast. It is safe.

Single toggle is the king of sales. It fits 80% of jobs. It is cheap. It is fast. Double toggle is the specialist. It is for the tough jobs. The nasty rocks. SBM makes both. We help you choose right.

Q1: Can I crush river pebbles with a Single Toggle?

A: You can. But be careful. Pebbles are round. They slip. They are hard. We suggest a low nip angle. Maybe 18 degrees. Or use a cone crusher after.

Q2: How often should I grease the bearings?

A: It depends on heat. Usually every 4 hours or 8 hours. Automatic lube systems are best. They don’t forget. SBM offers this.

Q3: My toggle plate broke. Why?

A: It did its job. Metal likely got in. Or the chamber was full at start. Never start full. Clear the rock first. Replace the plate.

Whatsapp:+8617329420102

Email: [email protected]

Address: No. 1688, Gaoke East Road, Pudong new district, Shanghai, China.

Online Service : Get Price

We value your feedback! Please complete the form below so that we can tailor our services to your specific needs.