Managing a 1000 TPH mine is a big job. You need strong machines. This article talks about heavy crushers. We explain how they work. We look at data. We show SBM success stories. Read this to choose the right tools.

1000 TPH means 1000 tons per hour. This is a huge amount of rock. It equals about 16 tons every minute. To do this you need heavy duty gear. Small crushers cannot handle this load. They will break fast.

We need high reliability here. The system must run 24 hours a day. Stops cost a lot of money. The feed size is usually large. It can be 1000mm or more. This requires a large intake opening. Why? To prevent blocking the machine.

Reference data from Mining Engineering journals suggests high throughput needs strong motors. We usually see motors over 600 kW. The torque must be high too. This ensures the machine starts under load.

For 1000 TPH, you have two choices. One is the Gyratory crusher. The other is the Jaw crusher. Let us look at them. The Gyratory is often better for this scale. Why? It crushes continuously.

The Jaw crusher crushes intermittently. It squeezes then opens. This is slower. The Gyratory spins and crushes all the time. It handles more rock. A 1000 TPH line needs a big Gyratory. SBM makes the KG series for this.

Working Principle involves a mantle. The mantle is on a main shaft. The shaft spins eccentric. This means it wobbles. It squeezes rock against the concave. The rock breaks. It falls down. This is simple and effective.

You must know these terms. They are vital for selection. First is CSS. This stands for Closed Side Setting. It is the smallest gap in the crusher. It decides the final size of the stone.

Next is OSS. This is Open Side Setting. It is the biggest gap. It affects how fast rock flows. Why? A bigger OSS lets more rock through. But the rock is bigger. You must balance this.

Other key data includes eccentric throw. This is how far the mantle moves. A big throw crushes faster. But it uses more power. You need to match the motor power. If the motor is small the machine stalls.

| Feature | Gyratory Crusher | Jaw Crusher |

|---|---|---|

| Throughput | Very High (up to 3000 TPH) | Medium (up to 800 TPH) |

| Feed Size | Large | Large |

| Maintenance | Complex top service | Simple toggle plate |

| Cost | High initial investment | Lower initial cost |

This is a common pain point. You buy a machine. The liners wear out in a week. You lose money. Why does this happen? Usually it is the material. If rock contains silica it is abrasive.

Silica is like glass. It cuts the steel. You need Manganese steel. We use Mn18Cr2 usually. Why? It gets harder when hit. This is called work hardening. It lasts longer.

Another reason is the chamber shape. If the shape is wrong wear is uneven. You must check the wear profile. SBM designs optimize the curve. This makes wear even. It extends life by 20% typically.

Let us look at a real job. The project was in Chile. The altitude was 3000 meters. The air is thin there. Motors cool slowly. The client needed 1000 TPH copper ore crushing.

The rock was hard granite. Hardness was f=18. This is very hard. They used old machines before. Those broke often. The shafts cracked. They came to SBM for help.

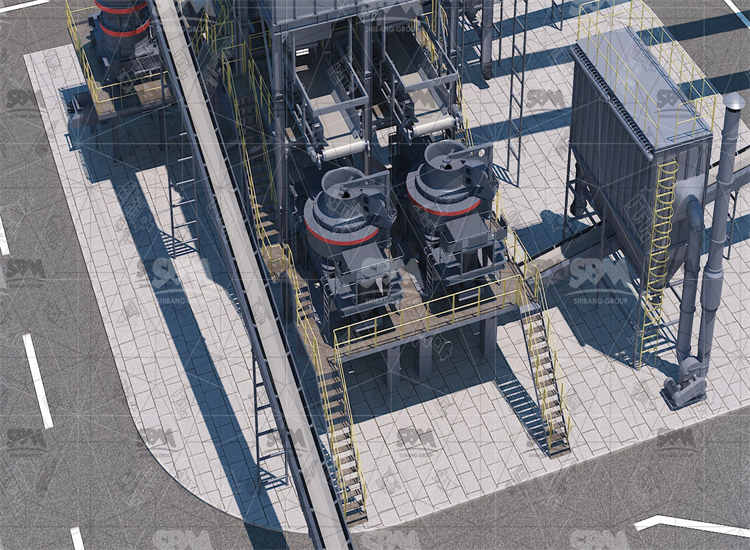

We installed one KG Gyratory Crusher. We also put in three HP Cone Crushers. Why? To step down the size. The primary breaks to 150mm. The cones break to 40mm.

The results were good. The client was happy. The capacity hit 1100 TPH sometimes. This beat the target. The energy use dropped. It went down by 15% per ton.

The maintenance manager said: “SBM machines are tough. We only change liners every 4 months. Before it was every month. This saves us labor.” This is real feedback. It shows quality.

We tracked the data for a year. The uptime was 98%. The 2% down time was for oil changes. No major parts broke. This proves high reliability.

Energy costs are high. You want to save bills. How do we do this? First use the right motor efficiency. We use IE3 or IE4 motors. They waste less heat.

Second keep the chamber full. This is called “choke feed”. Why? Rock crushes rock. This is efficient. If the chamber is empty you crush air. That wastes power.

SBM automation helps here. We use sensors. They see the level. They speed up the feeder. They keep the crusher full. This saves about 10% energy. It also makes stone shape better.

Do not guess. Use data. Look at the Bond Work Index. This tells you hardness. If the index is over 16 you need heavy duty. If under 10 standard duty is fine.

Check the moisture content too. If wet sticky mud enters it blocks. You need a steeper chamber. Standard is 50 degrees. For wet we use 60 degrees. Why? Gravity helps mud slide.

We simulate the flow. We use software. It shows where rocks go. We adjust the speed. We adjust the throw. This is engineering; not guessing.

Another case is in Nigeria. This was for construction stone. The demand is huge there. They needed 1000 TPH for road base. The stone is abrasive granite.

They used SBM Jaw Crushers in parallel. Two PE1200x1500 jaws. Why? To share the load. If one stops the other runs. This keeps production going.

The customer liked the installation. Our engineers went there. We taught them how to weld. We taught them lubrication. The plant runs smooth now. They produce 20 hours a day.

You worry about parts. If a part breaks you stop. SBM has warehouses globally. We keep spare shafts. We keep spare bushings. You get parts fast.

Design matters for maintenance. Our crushers use hydraulic release. If iron gets in the top lifts up. The iron passes through. Why? To protect the machine. No manual digging needed.

We also have a lube station. It cools the oil. It filters the dust. Clean oil means long life. You just check the gauge. It is simple for workers.

The answer is maybe. A large Gyratory can do it. A single Jaw usually cannot. The biggest Jaw is around 800 TPH. You would need two Jaws.

Using one machine is risky. If it breaks production is zero. Two machines are safer. But one big machine is cheaper to build. You must decide risk versus cost.

Most big mines use one Gyratory. It is standard. They trust the reliability. SBM Gyratory is built to not fail. It is very heavy steel.

Oil is the blood of the machine. You must change it. Usually every 2000 hours. Or every 6 months. But check it weekly.

Look for metal flakes. Use a magnet. If you see metal the bearing is wearing. Stop and check. Why? To save the shaft. Oil analysis is a good tool.

SBM provides a schedule. We give a book. It tells you when. Follow the book. Your machine will last 20 years. Ignore it and it dies in 2.

Crushers are loud. 1000 TPH is very loud. It can be 110 decibels. This hurts ears. You must protect workers.

We use rubber mounts. They stop vibration. This lowers noise. We also use dust covers. They trap noise inside. It helps a little.

Always wear ear plugs. SBM designs assume safety first. But rocks breaking makes noise. You cannot stop physics. Distance is the best protection.

Installing a 100 ton machine is hard. You need a good foundation. Concrete must be thick. It must cure for 28 days. Do not rush this.

Use anchor bolts. They must be tight. Check them after one week. Vibration loosens them. Why? Loose bolts crack concrete.

Align the motor. Use a laser tool. If belts are crooked they snap. SBM engineers help align. We bring the laser. Precision saves belts.

A 1000 TPH plant costs millions. But it makes millions. The ROI is usually 1 to 2 years. This depends on stone price.

Do not buy cheap machines. Cheap machines break. One day stop is $50,000 lost. Buy quality SBM machines. You pay more once.

Calculate the cost per ton. Include power. Include wear parts. Include labor. SBM machines have low cost per ton. This is where profit comes from.

To summarize 1000 TPH is big business. You need a Gyratory or big Jaws. You need automation. You need good liners.

Check your rock hardness. Check your power supply. Talk to SBM experts. We help you design the flow. We have done this many times.

Do not wait. The market is good. Get the right equipment. Start producing. Contact SBM for a quote today.

| Capacity | Primary | Secondary |

|---|---|---|

| 500 TPH | PE Jaw | HP Cone |

| 1000 TPH | KG Gyratory | Multi Cylinder Cone |

| 1500 TPH | Giant Gyratory | Custom Cone |

Whatsapp:+8617329420102

Email: [email protected]

Address: No. 1688, Gaoke East Road, Pudong new district, Shanghai, China.

Online Service : Get Price

We value your feedback! Please complete the form below so that we can tailor our services to your specific needs.