Do you want more tons per hour. Every mine boss wants that. The secret is often hidden in a small gap. This gap is the Closed Side Setting (CSS). It controls your profit; Many people ignore it. This guide helps you fix it. We use data from real mines. We explain it simply. You can reduce wear and tear. You can save energy too? Let us look at how SBM helps you.

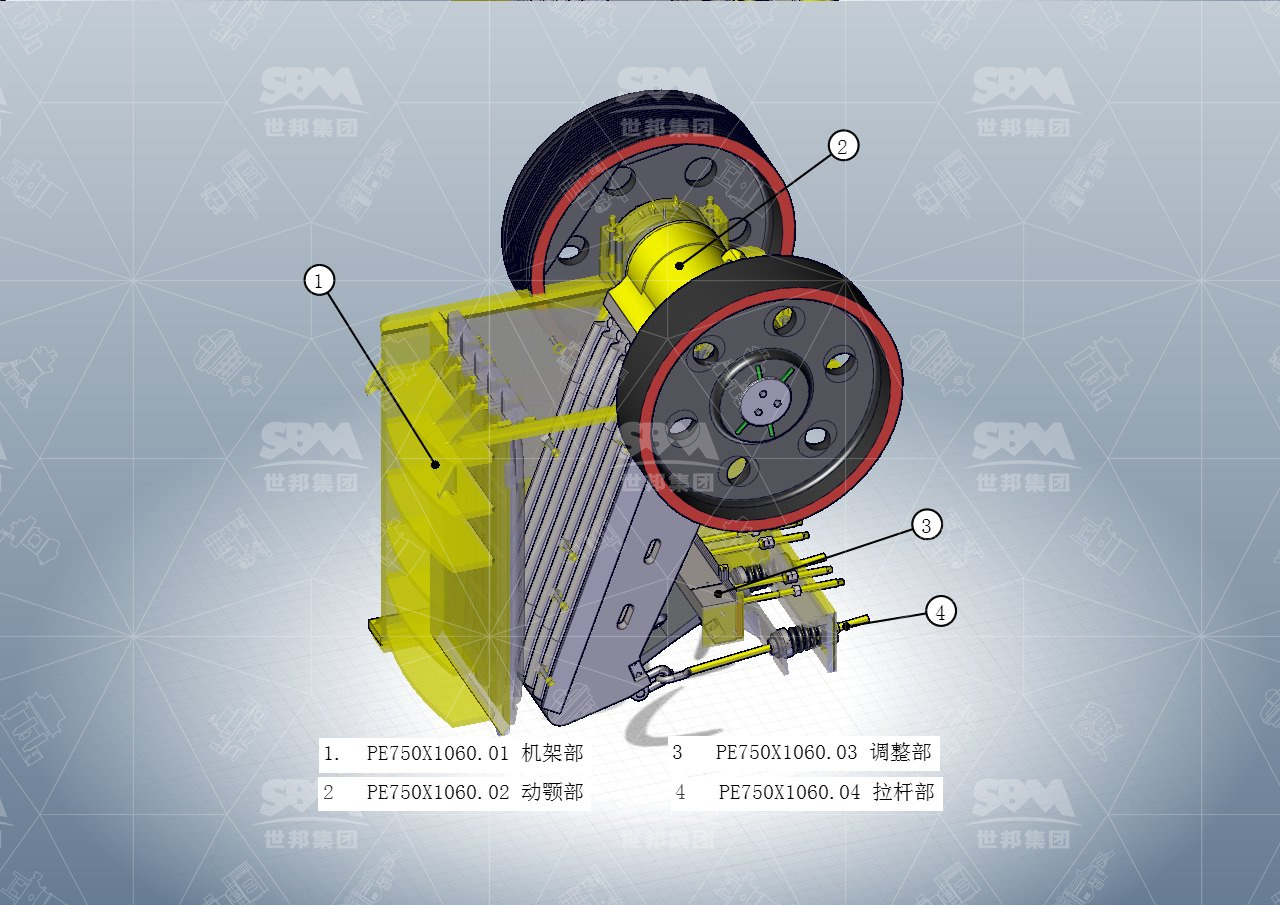

First we must define the terms. The jaw crusher has two plates. One moves and one is fixed. The rock gets crushed between them. The moving jaw goes back and forth. This is the stroke.

CSS Definition: The CSS is the smallest distance between the plates. It is measured at the bottom of the crushing chamber. You measure it during the crushing cycle. It happens when the jaw is closest to the fixed plate.

Why it matters:

There is also the OSS. This is the Open Side Setting. It is the largest gap. It happens when the jaw pulls back. The relationship is simple. OSS equals CSS plus the throw. The throw is the distance the jaw moves.

You need to know your machine. A jaw crusher uses compressive force. The motor spins a flywheel. The flywheel moves an eccentric shaft. This moves the pitman. The pitman holds the moving jaw die.

Key Parameters to Watch:

Reference data from Minerals Engineering journal shows facts. A correct CSS reduces recirculation load by 15%. This saves electricity. It also stops the secondary crusher from choking. You must balance the CSS with the feed size.

Is your crusher sick. Look for these signs. They mean your CSS is wrong.

The Solution: You must adjust the setting. Do not guess; Use a gauge. Measure the gap. Check the manual.

There are three main ways to do this. It depends on your machine age. It depends on the model too.

This is the old way. You use steel plates. They are called shims. You put them behind the toggle block.

This is faster. It uses two wedges. A screw moves them.

This is the best way. SBM uses this often. It uses oil pressure.

Data is king. Look at this table. It shows a test with Granite. The rock hardness was 150 MPa. See how CSS changes the product.

| CSS Setting (mm) | % Passing 75mm | % Passing 50mm | Energy (kWh/t) |

|---|---|---|---|

| 75 mm | 85% | 55% | 1.45 |

| 100 mm | 65% | 40% | 1.10 |

| 125 mm | 50% | 30% | 0.95 |

Analysis: A tighter CSS (75mm) makes finer rock. But energy goes up. A loose CSS (125mm) saves power. But the rock is big. You must choose the balance.

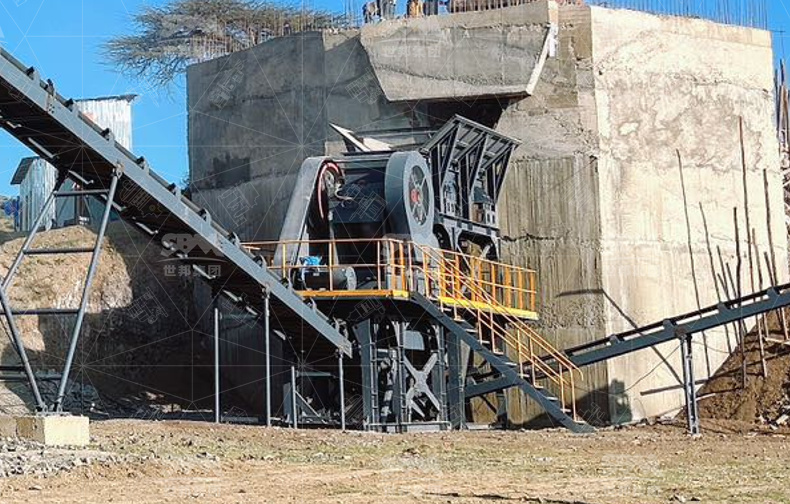

Project Background:

A client in Peru had a problem. They process hard granite. The altitude is 4000 meters. The air is thin. Cooling is hard.

The SBM Solution:

We analyzed the “work index”. The rock was very hard. We opened the CSS to 90mm. We installed a curved jaw plate. This changed the nipping angle.

The Results:

Why it worked: Opening the CSS lowered the pressure. The curved plate gripped the rock better. This prevented slipping.

This is a common question. Operators hate this. One day the rock is small. The next day it is big.

The Cause: Liner wear is the culprit. As you crush rock; steel wears away. The CSS gets bigger every day. You might not see it.

The Fix: Measure the gap daily. Adjust the CSS weekly. Do not wait for it to look bad. SBM machines have easy adjusters for this reason.

Project Background:

This was a cement plant. Limestone is soft but sticky. It rains a lot there.

The SBM Solution:

We used a hydraulic CSS system. It has an auto-clear function. If pressure spikes; the jaw opens. It clears the mud. Then it resets.

The Results:

Why it worked: The hydraulic system reacts fast. It prevents packing. It protects the motor from burning.

Do not guess. Use math. It is simple math.

The Rule of Thumb:

The CSS should be slightly smaller than the required product size. But; it must allow for “bulking”.

Formula: Expected Top Size = CSS x 1.4 (for standard rock). If your CSS is 100mm, your top size is about 140mm. Some flat rocks will slip through.

Check the Secondary Crusher:

Look at the next machine. Is it a Cone Crusher? What is its feed opening? The Jaw CSS must make rocks small enough for the Cone. If the Cone takes 150mm; set Jaw CSS to 100mm.

A good machine needs love. Treat it well. It will make money.

Installation:

Maintenance Checklist:

Why do this: Loose bolts break castings. Uneven feed wears plates wrong. Good feed extends life.

No. Definitely not. This is a myth.

The Risk: If CSS is too small; the rock cannot exit. It stays in the chamber. It gets crushed again and again. This is “over-crushing”.

The Consequence:

The Lesson: Crush only as much as needed. Let the secondary crusher do its job.

We won’t list every dollar. Every site is different. But the logic is the same.

The Cost of Bad CSS:

The Gain with SBM:

Our crushers allow fast adjustment. You keep the CSS optimal. If you save 15 minutes a day; that is 90 hours a year. That is 10,000 tons of extra rock. The machine pays for itself.

Optimizing CSS is not hard. It requires discipline. It requires the right machine. You understand the physics now.

Recap:

Mining is tough business. Your equipment should be tough too. SBM provides the tools. You provide the drive. Together we build efficiency. Check your CSS today. Your profit margin depends on it.

Whatsapp:+8617329420102

Email: [email protected]

Address: No. 1688, Gaoke East Road, Pudong new district, Shanghai, China.

Online Service : Get Price

We value your feedback! Please complete the form below so that we can tailor our services to your specific needs.