Crushers are the heart of a mine. If they stop; money stops. The cone crusher is a key machine. It has two main wear parts. One is the mantle. The other is the concave. They crush the rock. But they wear out. Knowing when to change them is vital. It saves money. It keeps production high. Many people change them too early. This wastes parts. Others change them too late. This hurts the machine. We will explain when to change them. We will use simple words. SBM has much experience here. We help mines run better.

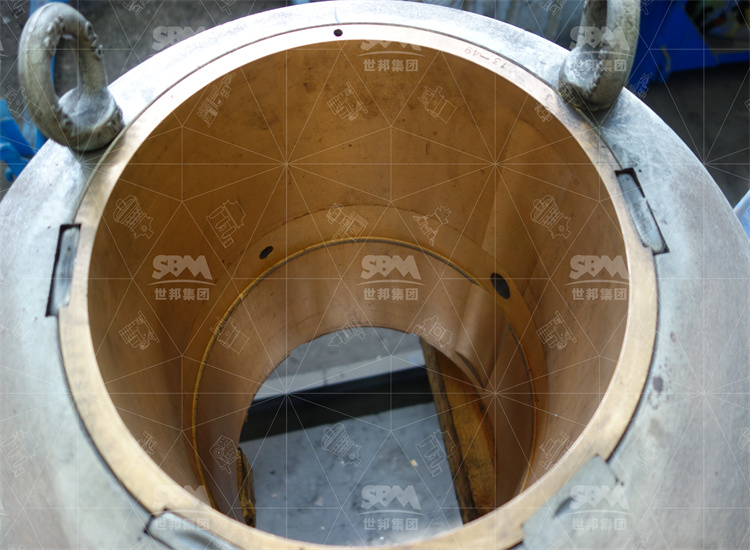

First we must know the parts. The mantle moves. It sits on the main shaft. It spins like a top. The concave does not move. It sits on the top shell. It is like a bowl. The rock goes between them. The mantle wobbles. It squeezes the rock against the concave. This breaks the stone. We call this the “crushing chamber”.

These parts are made of special steel. It is Manganese steel. We usually use Mn13Cr2 or Mn18Cr2. This steel is smart. When rock hits it; it gets harder. This is called “work hardening”. But it still wears down. The gap between them gets bigger. This gap is the CSS. CSS stands for Closed Side Setting. It decides the stone size. If the parts wear; the CSS changes.

Watch your output. This is the first sign. Is the pile of crushed rock smaller? The machine might run fast. But less rock comes out. Why does this happen? Because the liners are thin. The crushing angle changes. The rocks slip. They do not break well.

You must check the Tons Per Hour (TPH). Compare it to last month. If it drops by 10% or more; check the liners. Do not wait. Lost production costs more than new parts. SBM engineers see this often. A simple check saves the day. Keep a log book. Write down the daily output. It helps you see the trend.

Look at the stones coming out. Are they too big? This is bad. It means the gap is too wide. The mantle and concave are worn. They cannot squeeze tight enough. We call this “oversize”.

Oversize rocks hurt the next machine. If you have a ball mill; it works harder. It uses more power. This wastes electricity. You want small rocks. Small rocks make the mill happy. If the CSS is set to minimum but rocks are still big; change the liners. The adjustment ring cannot go lower. The metal is gone.

Do not just guess. You must measure. Stop the machine. Lock it out for safety. Open the chamber. Look at the bottom of the mantle. Look at the bottom of the concave. Most wear happens here. This is the “parallel zone”.

Use a simple rule. We call it the 50% rule. Is the liner thickness half of what it was? If it was 50mm and now is 25mm; be careful. Some brands say change at 2.5cm thickness remaining. If it gets too thin; it cracks. A cracked liner destroys the crusher body. That is very expensive.

Here is a data table for wear limits. It helps you decide.

| Liner Type | Original Thickness (mm) | Change Point (mm) |

|---|---|---|

| Standard Mantle | 60 – 80 | 20 – 25 |

| Heavy Concave | 80 – 100 | 25 – 30 |

| Short Head | 50 – 70 | 15 – 20 |

Let us look at a real job. SBM helped a gold mine. It is in Tanzania. The rock is hard granite. It is very abrasive. The customer had a problem. Their liners broke every 2 weeks. This was too fast. They lost money on downtime.

The Details:

– Equipment: SBM PYY 900 Cone Crusher.

– Material: Gold ore (Granite).

– Feed Size: 150mm.

– Output Size: 20mm.

We looked at the old liners. They were worn unevenly. The bottom was thin. The top was thick. Why? The feed was bad. They did not fill the chamber. We call this “starvation feeding”. The rock hit only the bottom. We fixed the feeder. We told them to “choke feed”. This means keep the cone full. We also used Mn18Cr2 steel. The result? The liners now last 6 weeks. The customer was happy. “SBM saved our production,” the manager said. It was a simple fix.

Some bosses want to save money. They use the liner until it breaks. This is dangerous. Why is it dangerous? Because the liner protects the costly parts. The liner protects the Main Shaft and the Bowl.

If the liner cracks; the pieces fall. They go into the gears. They break the gears. A liner costs $2000. A new shaft costs $20,000. Do the math. It is not worth the risk. Also; thin liners flex. This flexing damages the backing material. The backing holds the liner tight. If backing fails; the liner spins. This cuts the head. Always change before it cracks.

Sometimes the liner is not worn out all over. It is worn only on one side. Or it is worn in a ring. This is “grooving”. It happens when feed is segregated. Segregated means big rocks one side; small rocks other side.

This causes bad forces. It shakes the machine. It ruins the bearings. If you see grooves; change the liner. Do not wait for it to get thin. You must also fix the feed chute. Make the rocks fall into the center. This makes wear even. Even wear means long life.

Watch the ammeter. The ammeter shows motor power. A good crusher runs steady. The needle stays still. If liners are worn badly; the needle jumps. This is a “power spike”.

Why does it jump? Because the profile is wrong. The crushing cavity is deformed. The rocks pack together. They do not flow. The motor fights hard to turn. Then it slips. Then it fights again. This burns the motor. If amps are high but tons are low; change the liners immediately. It is an urgent sign.

Another story from SBM. This was an iron mine in Pilbara. The scale was huge. They needed 500 tons per hour. They used a competitor’s crusher. The liners lasted 400 hours. They wanted 600 hours.

We checked the data. The iron ore was wet. It was sticky. The fines (dust) stuck to the concave. This is “packing”. It caused high pressure. The liners cracked early. SBM suggested a new cavity shape. We used a “Coarse” cavity. It has a wider mouth. It lets dust pass through. We installed SBM custom liners. The result was great. The liners lasted 650 hours. The cost per ton went down $0.15. This is a lot of money in iron ore.

You bought new parts. Now you install them. Be careful here. Bad installation kills new parts. First; clean the surfaces. The head and bowl must be clean. No rust. No oil.

Second; check the backing. You must pour new backing material. It is like glue/epoxy. It fills the gaps. It stops the liner from shaking. If you miss spots; the liner will break. SBM provides clear guides for this. Always let the backing cure (dry). Usually wait 24 hours. Do not rush.

Third; run it empty first. Let it spin for 2 hours. Listen to the sound. It should be smooth. Then add rocks slowly. Do not go 100% full immediately. Let the parts settle.

We know you have questions. Here are three common ones. We hear these every day.

No! Never weld a manganese liner. Why? Because heat changes the steel structure. It makes it brittle. Brittle means it shatters like glass. If you weld it; it will crack under load. It creates a weak spot. It is unsafe. Just buy a new one. It is cheaper than an accident.

This is a backing problem. Did you pour the epoxy correctly? Maybe it was too cold. Maybe you did not mix it well. Or maybe the nut on top is loose. The “mantle nut” must be tight. If it is loose; the mantle spins. Check the nut. Check the backing. Re-tighten the nut after the first 8 hours of work.

It depends on your rock. Mn13 is standard. It is good for soft to medium rock. Limestone or coal. Mn18 is harder. It has more manganese. It is for hard rock. Granite or basalt. Mn18 costs more. But it lasts longer in hard rock. If you crush soft rock with Mn18; it might not “work harden”. It wastes money. Ask SBM experts to choose for you.

Think about value. Not just price. A cheap liner costs $1000. It lasts 200 hours. That is $5 per hour. A SBM liner costs $1500. It lasts 400 hours. That is $3.75 per hour. The “expensive” one is actually cheaper.

Also consider downtime. Every time you stop to change; you lose production. If you produce 100 tons an hour; and rock is $50 a ton; you lose $5000 an hour. Changing takes 8 hours. That is $40,000 lost. You want to change less often. Better liners mean less stops. Less stops mean more profit.

Replacing mantles and concaves is normal. It is part of mining. But timing is key. Do not be too early. Do not be too late. Watch the amps. Watch the tons. Measure the gap.

Look for the signs. Drop in capacity. Big rocks in product. Power spikes. These tell you it is time. Choose the right material. Mn13 or Mn18. Install it well. Use good backing. SBM is here to help. We make parts that last. We help you make money. If you are not sure; call us. We can check your wear profile. We can suggest the best plan.

Whatsapp:+8617329420102

Email: [email protected]

Address: No. 1688, Gaoke East Road, Pudong new district, Shanghai, China.

Online Service : Get Price

We value your feedback! Please complete the form below so that we can tailor our services to your specific needs.